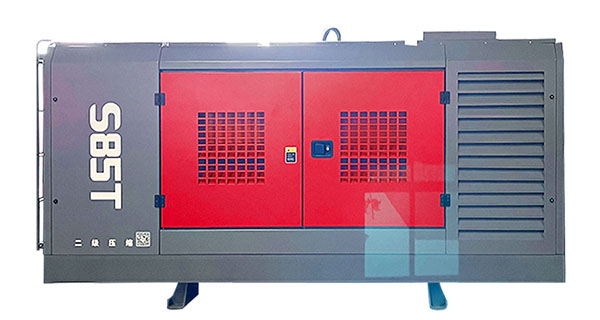

D miningwell air compressors used for rock drilling rig

In order to ensure the normal and smooth operation of the screw air compressor, the air compressor operator should strictly follow the correct switching steps. Do you know the precautions for the switch operation of the screw air compressor?

▶ Precautions before starting up:

1. Check the three-phase power supply and confirm that it is normal.

2. Open the door lock of the machine and observe the oil level of the air compressor. At this time, the oil level cannot be lower than the lowest level, otherwise the coolant needs to be supplemented to the normal position.

3. Turn on the power of the controller and observe whether there is any abnormal display on the LCD screen. “The device has been shut down” is displayed, indicating that it is normal.

4. Open the outlet valve of the air compressor.

5. After the above check is correct, you can press the air compressor start button, that is, the (ON) button, and the air compressor can work normally.

▶Operation precautions:

1. After turning on the machine, observe the operation of the air compressor for 3 to 5 minutes. Observe whether there is abnormal noise and vibration, whether there is leakage of oil, gas, etc., otherwise it should be stopped immediately for inspection.

2. There is pressure in the rotating pipeline and container. It is strictly forbidden to loosen the pipeline or plug, and open unnecessary valves.

3. Pay attention to the oil level during operation. When the machine is running, the oil level is lower than that after the machine is stopped, which is a normal phenomenon. When the oil level cannot be seen, and the exhaust temperature reaches 100 degrees, it should be stopped immediately. Observe the oil level after 10 seconds of shutdown, if it is insufficient, add lubricating oil when there is no pressure in the system;

4. After the gas is cooled by the cooler, a certain amount of condensed water will be produced, which should be discharged regularly, otherwise the water will be brought into the rear system by the gas; the water discharge time can be flexibly adjusted according to weather reasons, generally more frequent in summer.

5. During operation, parameters such as voltage, current, outlet gas pressure, outlet exhaust temperature, and oil level should be recorded at least every day for future maintenance and reference.

▶Stopping precautions:

1. First press the OFF button, after 10 to 15 seconds, the intelligent controller stops according to the pre-programmed program. The motor will stop. Avoid direct shutdown of the air compressor under heavy load;

2. If necessary, press the emergency stop switch (red button) to cut off the power supply of the main controller and the contactor.

3. After the air compressor is stopped, it cannot be started immediately. It takes about 1 to 2 minutes to wait for the system to automatically empty the internal pressure to prevent the motor from being damaged by heavy load startup.

4. After the air compressor is debugged, adjust the pressure and other parameters according to the actual situation, and set it to automatic control mode. Under normal circumstances, users do not need to adjust by themselves.