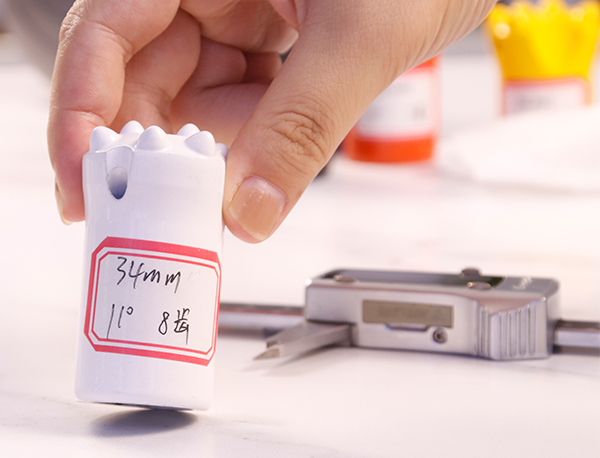

D miningwell blasting drill tool 32mm 34mm 36mm 38mm 40mm 42mm mine drilling machine portable tapered bit

The rock drilling tool is a tool for human beings to conquer rock and ore. Its structure is composed of a slender hollow drill pipe and a drill bit inlaid with rock drilling carbide. In the process of rock drilling, under the conditions of severe wear and tear of rock ores and erosion and corrosion of high-pressure water flow (or compressed air) and pit water, the drill rod and drill bit are subjected to various forces such as tension, compression, bending, and torsion, and the rock drill is 2000 per minute. The high frequency impact of ~3000 times, and the impact energy per impact is as high as 25J~500J, so the drill rod and drill bit often fail by stress corrosion fatigue fracture, and their service life is generally only ten minutes to dozens of hours. Therefore, rock drilling tools are a large number of consumable tools that are indispensable in basic industries with harsh stress conditions, short service life and high technical content among all human steel tools.

Drill bit classification:

tapered button bit drills directly into rock, which is the most vulnerable part in rock drilling tools. It is composed of rock drill carbide inlaid on the drill bit body. According to the shape of the rock drilling alloy used, the drill bits can be divided into the following categories: chip drill bits (mainly one-shaped drill bits, three-edged drill bits, cross-type drill bits, X-type drill bits), cylindrical tooth drill bits (with ball-tooth drill bits, high and low air pressure DTH drill bits), chip-tooth composite drill bits, roller cone drill bits, etc.

Chip bits are used for surface operations, while roller cone bits are mainly used for drilling and exploration. Due to factors such as structure and force, the chip-shaped drill bit has low rock crushing efficiency, slow footage, large amount of alloy, and is prone to waste. Among them, the in-line drill bit accounts for more than 80%, which is mainly used for small hole and shallow hole rock drilling. The cross-type and X-type drill bits are mainly used for tough medium and deep holes. Moreover, the maximum diameter is limited due to structural and stress reasons. Generally, the diameter of the in-line drill bit is not more than 45mm, the cross-type drill bit is not more than 64mm, and the X-type drill bit is not more than 89mm, otherwise it is easy to cause alloy fragmentation and lead to early failure.

We manufacture various tapered button bits in different degrees as below:

Bit diameter: 26mm to 60mm;

Tapered degree: 4°46’, 6°, 7°, 11°, 12°;

Shank sizes: Hex. 19mm, Hex, 22mm and Hex. 25mm;

Carbide type: Chisel type, Cross type, Button type.

Qty of button: 5, 7, 8 pcs

| Technical Parameters | ||||||

| DIAMETER | BUTTONS | FLUSHING | CARBIDE | FACE | ||

| MM | IN | GAUGE NO/ SIZE | FRONT NO/ SIZE | HOLE | PROFILE | PROFILE |

| 32 | 1 1/4″ | 5×7 | 2×7 | IF1G | Parabolic | Flat |

| 36 | 1 13/32″ | 5×8 | 2×7 | 2F1G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 1F2G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 2F 1G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 2F1G | Conical | Flat |

| 40 | 1 9/16″ | 5×9 | 2×8 | 2F 1G | Conical | Flat |

| 41 | 1 5/8″ | 5×9 | 2×8 | 2F1G | Conical | Flat |

| 41 | 1 5/8″ | 5×9 | 2×8 | 2F 1G | Parabolic | Flat |