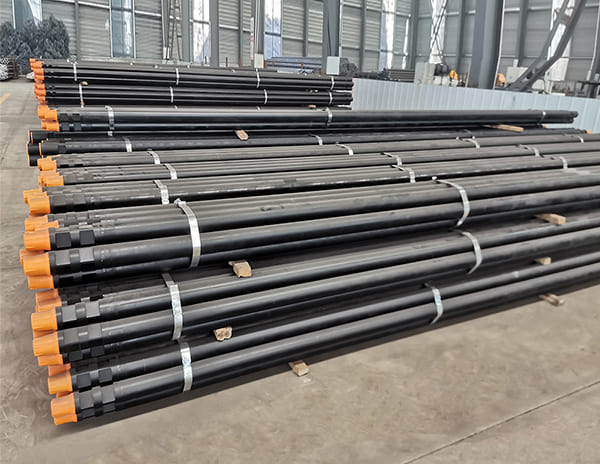

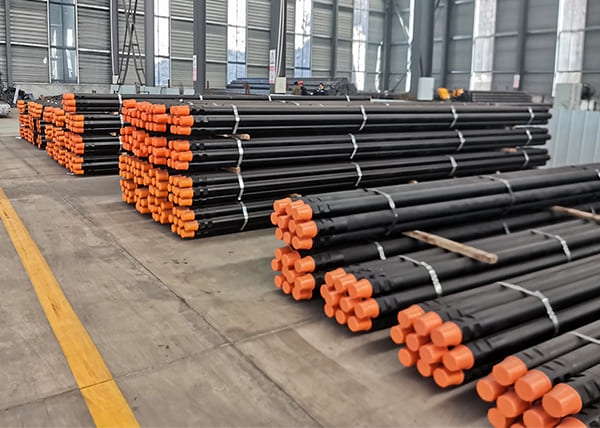

D miningwell dth drill rods well drilling rods hot rod bore well steel pipe

D Miningwell was founded in Quzhou city, China in 2001. For more than 29 years production and operation process. D Miningwell has been on the leading edge of mining equipment. We has its own drilling rig, DTH hammer, and drill pipe production workshops. provides a wide range of quality tools to mining, tunnelling, quarrying, water-well projects and urban transportation construction. D Miningwell is committed to providing customers with the most efficient and cost-effective drilling solution. Our team of drilling specialists are standing by to assist.

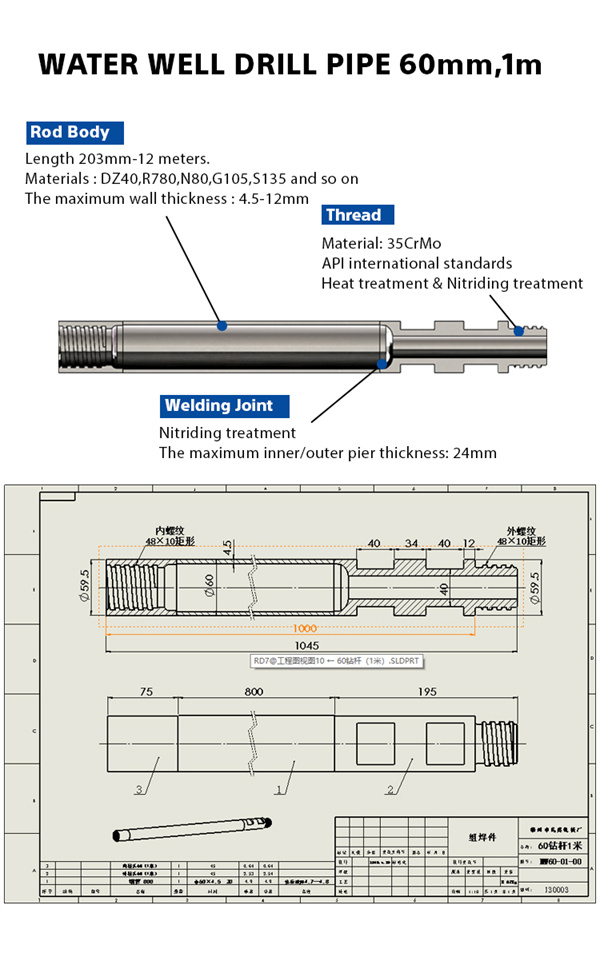

How to prevent thread breakage for friction welding drill pipe?

Thread cracking failures account for approximately 70% of drill pipe failures. According to the analysis of the causes of thread cracking failure, the following preventive methods can effectively reduce the occurrence rate of such failures:

(1) When machining threads, it is necessary to prevent incomplete threads from being generated at the end of the thread (retraction), so as to prevent the stress of the drill pipe from concentrating there, resulting in fatigue failure of the thread teeth.

(2) Appropriate sealing methods should be adopted at the bottom of the friction welding drill pipe coupling and the inner end of the external thread to prevent the fluid in the pipeline from entering the threaded joint as much as possible, reduce corrosion and wear, and prevent the threaded teeth from rusting, resulting in lack of strength.

(3) Non-destructive testing such as radiographic testing or magnetic particle testing is performed on the processed threads, and the surface and internal defects of the pipeline threads are found in time to prevent the defective threads from being tightened.

(4) Tighten the thread with an appropriate torque to prevent the thread teeth from cracking due to excessive pre-tightening force exceeding the strength limit of the thread material.