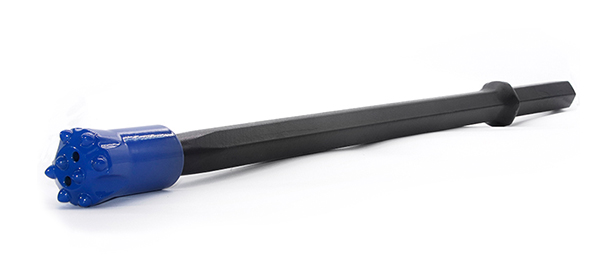

D miningwell Hole Drilling Tools R25 R28 R32 R38 T38 T45 T51 extension rod t51 4.8 m for jack hammer taper drill rod

D miningwell provides leading strength and penetration rates for more productivity, excellent straightness and hole clean quality, get max drilling performance to save up fuel cost rate.

D miningwell can design and manufacture according to customers’ samples or drawings of the length. Our taper rod is made by high quality steel, through heat treatment so that it can be used for hard rock drilling, and transmit intensive impact energy into the rock with the least possible loss of energy. Comparing with tapered chisel bits and tapered cross bits, button bits has higher technology, much longer primary drilling time and higher drilling efficiency.

How to use tapered rod accurately

Tapered rod should ensure that there is only enough mating surface with the tapered button bit. In general, the depth of the tapered drill rod inserted into the tapered button bit should be ≥25mm. Therefore, try to use tapered rods whose taper tips are machined by machining. The drill rod used in conjunction with the tapered button bit should be straight to the naked eye, and the impact end face of the drill tail should be flat. Whether it is a tapered bit or a tapered drill rod, the water hole should be kept clear.