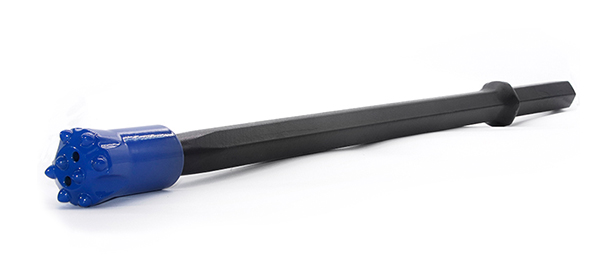

D miningwell Tapered Tools R25 R28 R32 R38 T38 T45 T51 speed rod t38 for breaking work taper drill rod

D miningwell provides leading strength and penetration rates for more productivity, excellent straightness and hole clean quality, get max drilling performance to save up fuel cost rate.

D miningwell can design and manufacture according to customers’ samples or drawings of the length. Our taper rod is made by high quality steel, through heat treatment so that it can be used for hard rock drilling, and transmit intensive impact energy into the rock with the least possible loss of energy. Comparing with tapered chisel bits and tapered cross bits, button bits has higher technology, much longer primary drilling time and higher drilling efficiency.

How to use tapered rod accurately

When using the tapered button bit and the tapered rod, firstly check whether the shank of the tapered drill rod is flat, whether the taper tip and the taper hole meet the requirements, whether the cutting edge of the tapered button bit is damaged, whether the water hole is not unblocked, and whether the air pressure water Whether the pressure is enough, the tapered button bit is strictly forbidden to collide with the alloys between the tapered button bits. When drilling holes, it should be noted that the wind must be light and light, that is, the wind pressure should be drilled with a small amount first, and then the wind pressure can be gradually adjusted to normal after the drilling is stable. When withdrawing the drill, try to reverse the drill and avoid forcibly knocking and pulling as much as possible, so as not to damage the tapered button bit or tapered rod, resulting in early scrapping.