Advantages and scope of application of friction welding drill pipe

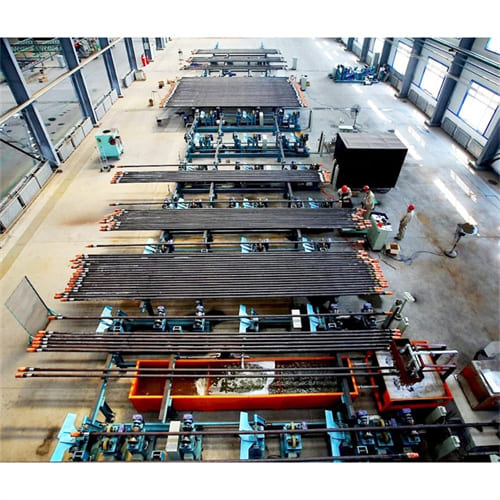

D miningwell is a professional enterprise engaged in the research, production and sales of drilling tools. Today, I will introduce the production advantages and application scope of friction welded drill pipes.

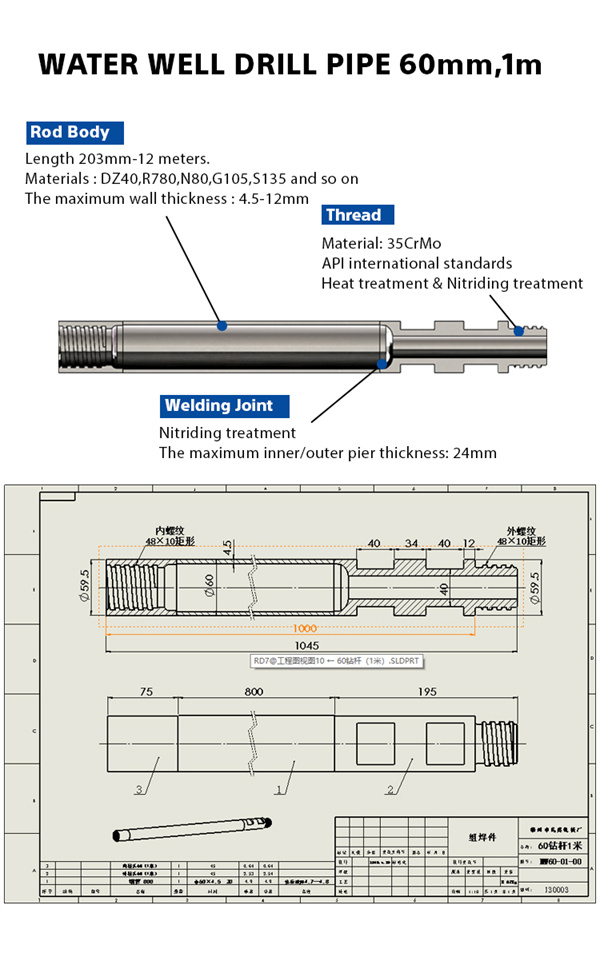

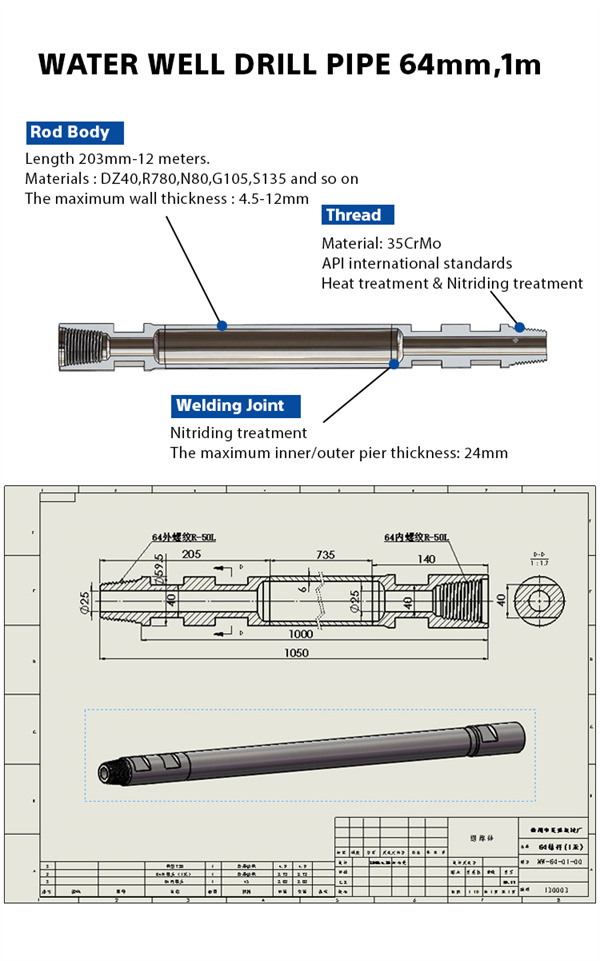

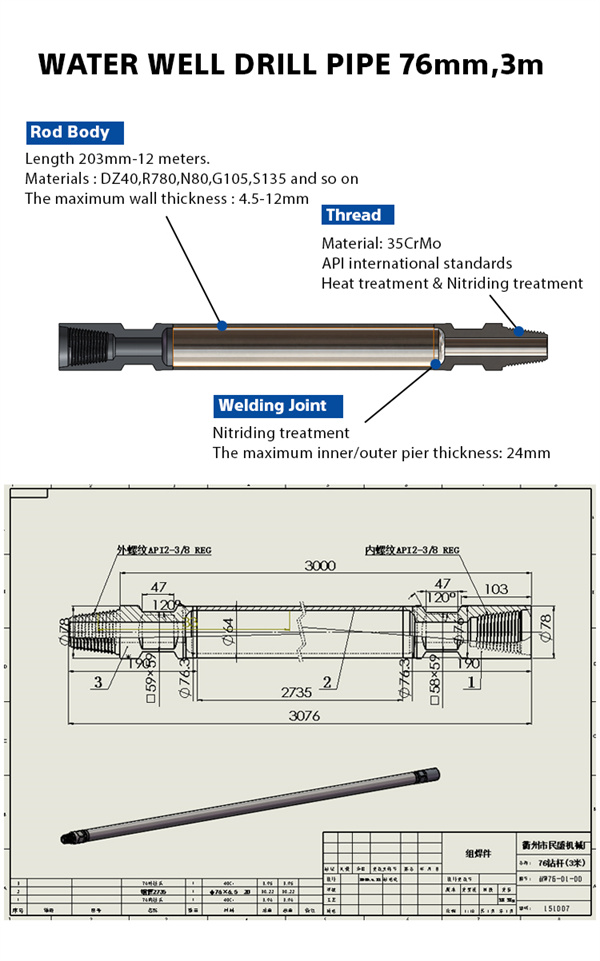

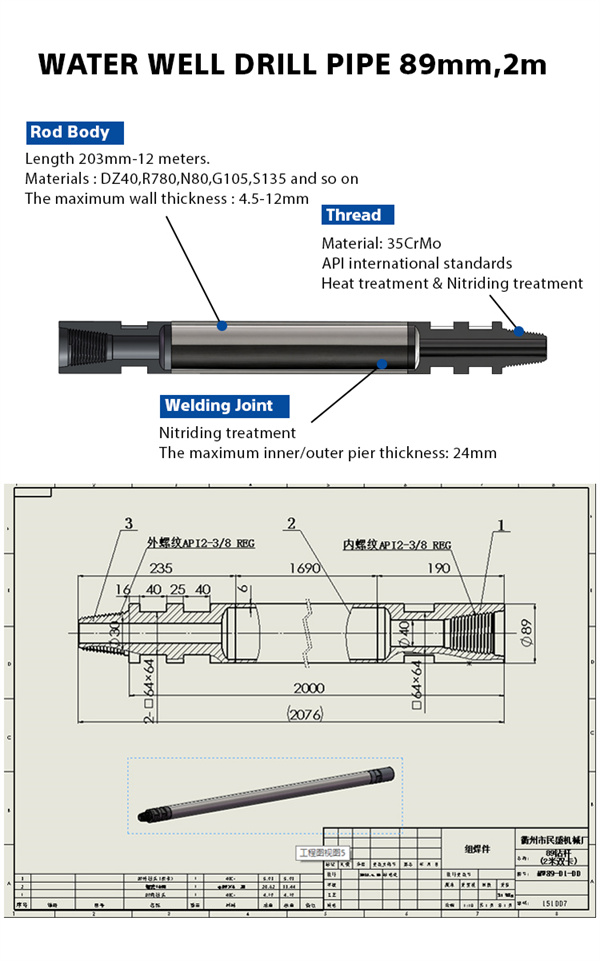

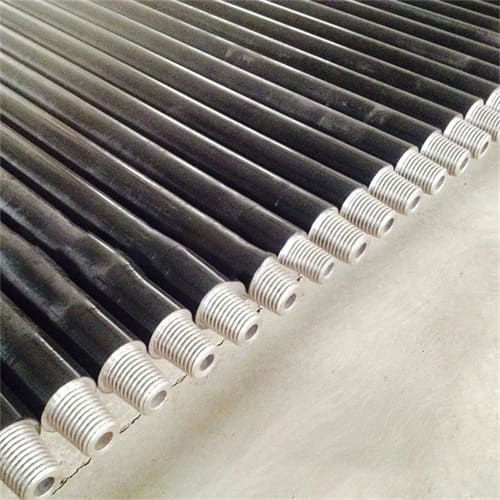

The combination of drill pipe requires welding, and there are various welding methods. Among them, the friction welding drill pipe is very popular among customers in the market. The friction welding process is cold working of the pipe body, which ensures the uniform thickness of the pipe body, the accuracy of the drill pipe, and also enhances the friction welding drill pipe. hardness and toughness.

Friction-welded drill pipe is mainly suitable for drill bits with threaded drills. It has the characteristics of good rotation and low resistance during rotary installation, and it is also relatively simple in the operation process, which is loved by people.

Friction welding drill pipe can be welded with different materials, which improves the quality of the drill pipe, which is different from other welding methods of drill pipe. The application of friction welding technology enhances the flexibility of the friction welded drill pipe and prolongs the service life of the drill pipe. According to the heat treatment of the inside of the drill pipe, the thickness of the weld is thickened and thickened, and the internal strength of the drill pipe is also greatly enhanced.