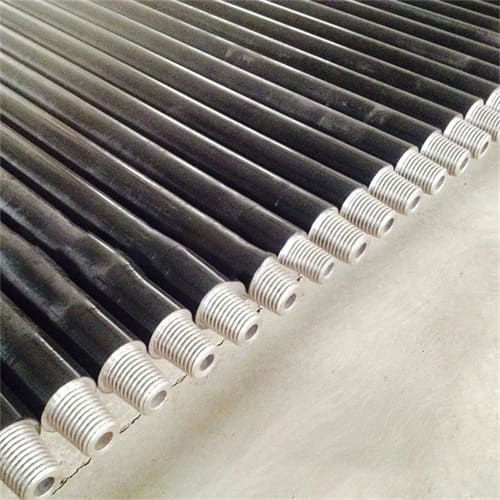

Factory drill rod for rock drilling length 1000mm – 6000mm Friction Welding hole drilling tool water drilling rods

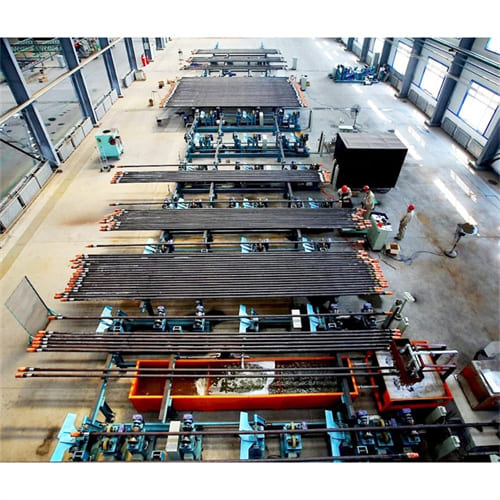

D Miningwell equips all rock drilling equipment with high-quality friction welded drill rods. The threads, rod bodies and welded joints of the drill pipes have been rigorously processed.

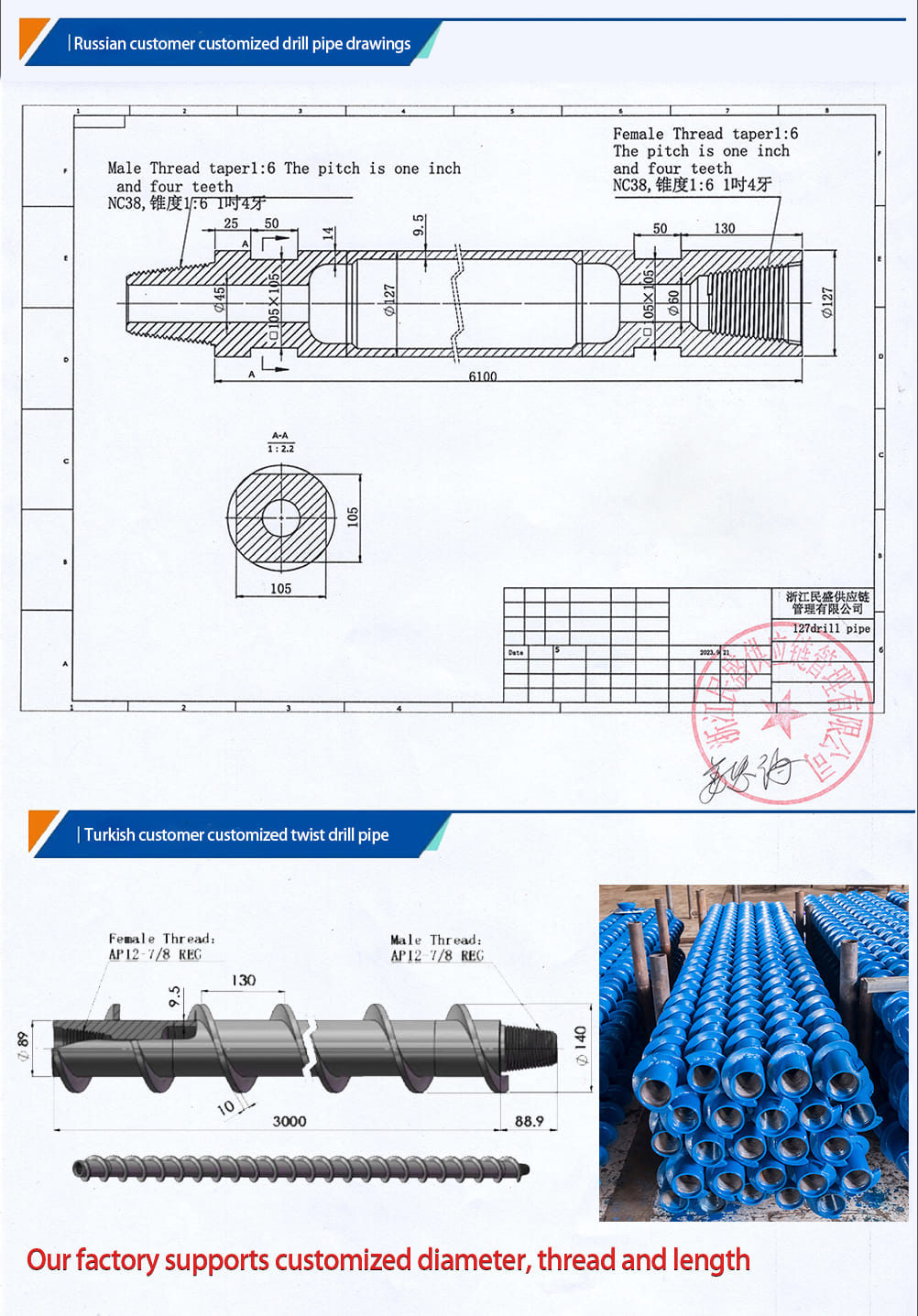

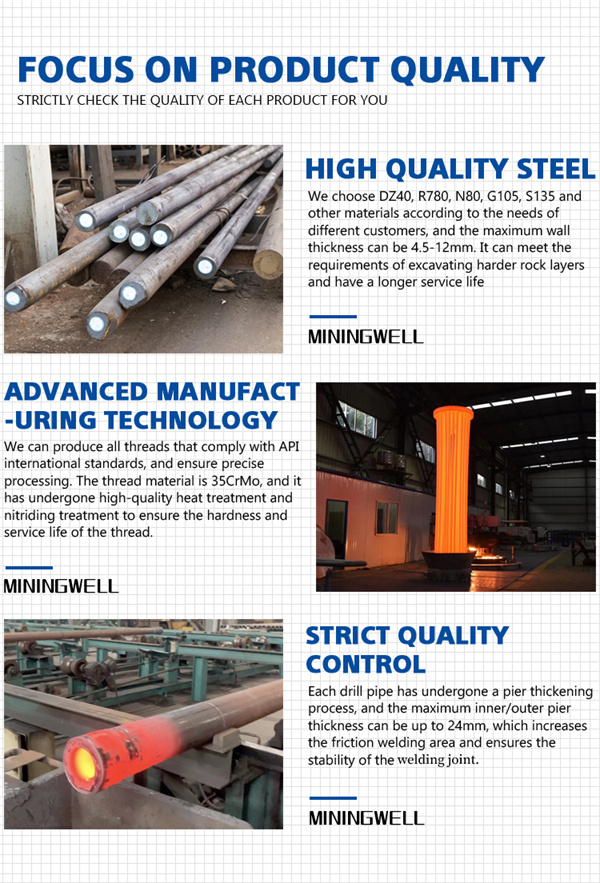

Thread: We can produce all threads that comply with API international standards, and guarantee precision processing. The thread material is 35CrMo, and it has undergone high-quality heat treatment and nitriding treatment to ensure the hardness and service life of the thread.

Rod body: We can supply drill rods with diameters of 42mm-203mm, and the maximum length can be made up to 12 meters. We choose DZ40, R780, G105, S135 and other rod materials according to the needs of different customers and the use scenarios of drill rods, and the wall thickness can be 4.5mm-12mm.

Welding joint: Each drill pipe has undergone a pier thickening process, and the maximum inner/outer pier thickness can be up to 24mm, which increases the friction welding area and ensures the stability of the welding joint.

Drill pipe application and storage maintenance

When tripping out, the drilling equipment should be strictly inspected one by one, and it is strictly forbidden to reuse the drill pipes and connectors that are damaged, cracked and the external thread fails to pass. Follow the operating specifications to avoid running drills, breaking drills, burning drills, etc., to prevent the drill pipe from being seriously damaged by super-strong pulling out. Cord-lock coring drill rods with external thread bonding connectors, check the inner surface before application to eliminate residual adhesive deposits. When drilling down to connect the vertical root, the drill pipe must be pulled up and buckled gently to avoid damage to the external thread of the connector. Use multi-contact pliers to unscrew the drill pipe, especially the rope lock core drilling equipment, and it is forbidden to knock.

The reserved drill pipe must be treated with anti-rust treatment. For the long-term storage drill pipe, it must be turned 180° and stored every week to avoid damage caused by natural bending. For drill pipe pins that cannot be disassembled, it is best to use small and medium-sized grinding wheels to drill holes, heating with electric drills, hammering with impact electric drills, symmetrical rotation and pressing, etc., and then use arc welding to cooperate with pin pullers. For disassembly, etc., oxygen cutting must be performed to maintain the integrity of the concave and convex joints as much as possible to ensure that they can be repaired to the original application requirements.

| Model | Diameter (mm) | Thickness(mm) | Thickening type | Length(mm) | Thread | Board shank slot |

| 1 | 76 | 5-8mm | IU | 1000/ 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 2 3/8 API REG | Double buckle Single buckle |

| 2 | 89 | 6-9.35mm | IU | 1000/ 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 2 3/8 IF | Double buckle Single buckle |

| 3 | 102 | 7-8.38mm | IU/IEU | 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 2 7/8 IF 3 1/2 REG | Double buckle Single buckle |

| 4 | 114 | 6-9.35mm | IU | 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 2 7/8 IF 3 1/2 IF/REG | Double buckle Single buckle |

| 5 | 127 | 9mm | IU | 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 3 1/2 IF | Double buckle Single buckle |

| 6 | 140 | 8-12mm | IU | 3000/ 4500/ 5000/ 6000 | 4 1/2 REG or 4FH | Double buckle Single buckle |