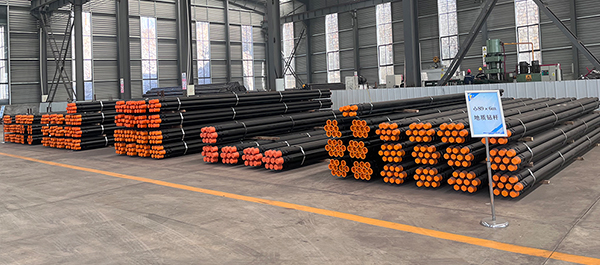

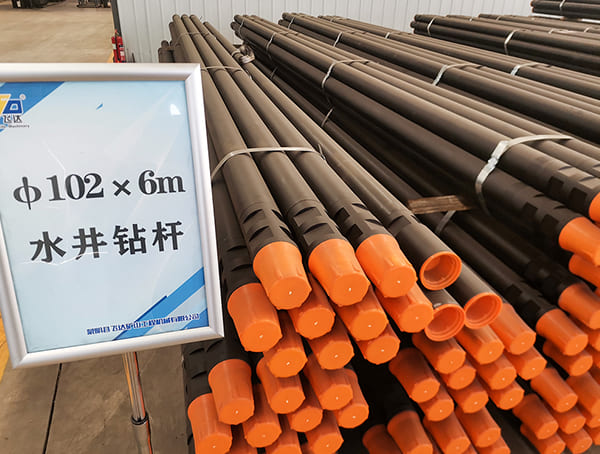

Factory made D miningwell 89mm Drill Pipe Water Well Drill Pipe Rod api reg if Dth Drill Pipe on promotion

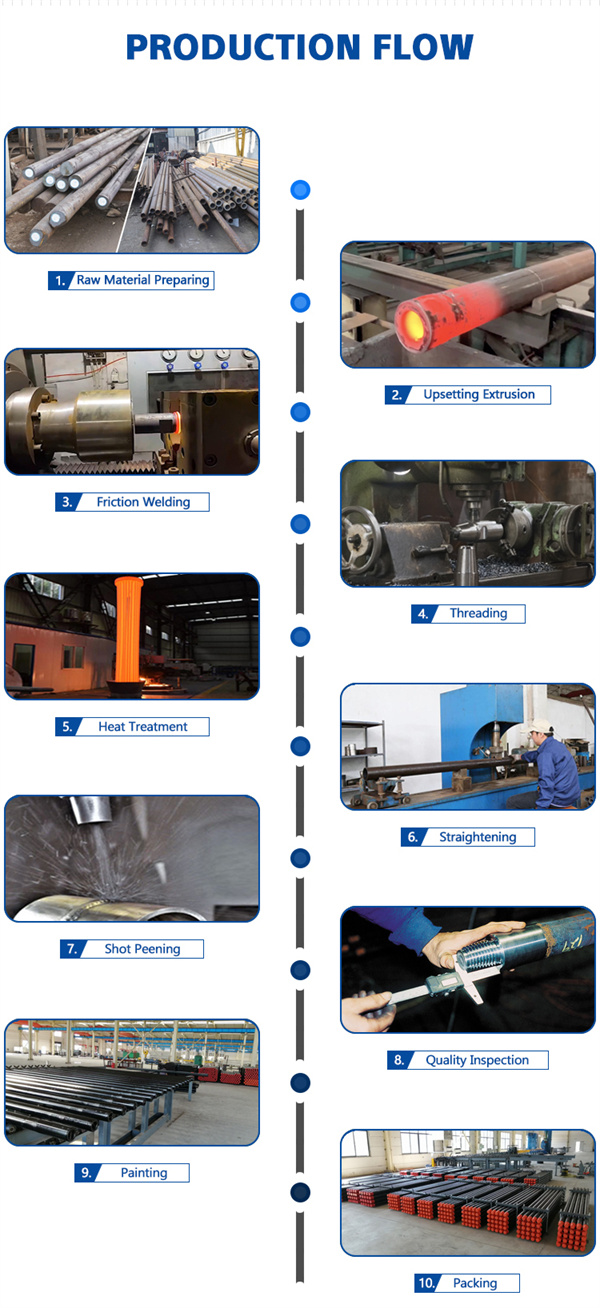

D Miningwell equips all rock drilling equipment with high-quality friction welded drill rods. The threads, rod bodies and welded joints of the drill pipes have been rigorously processed.

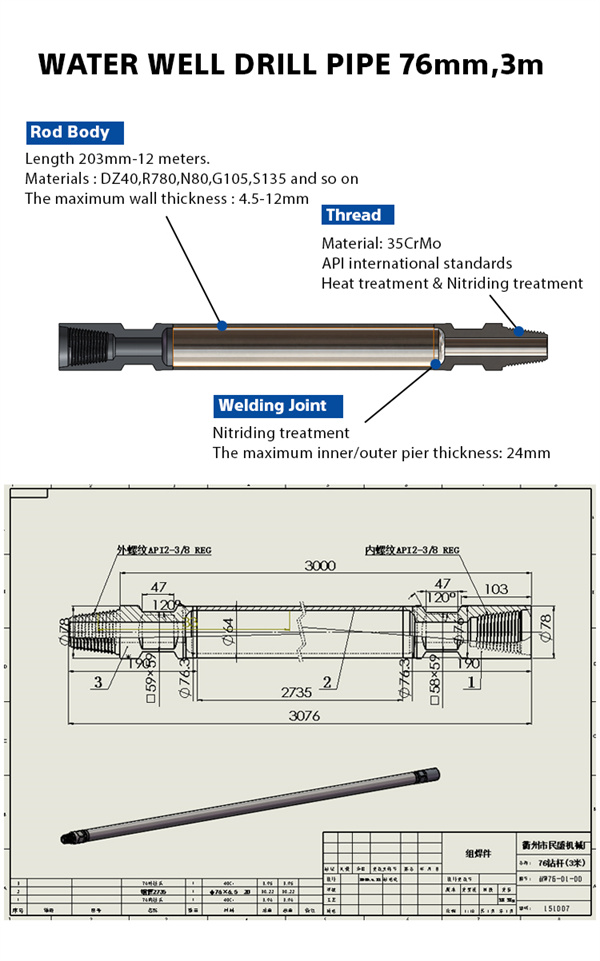

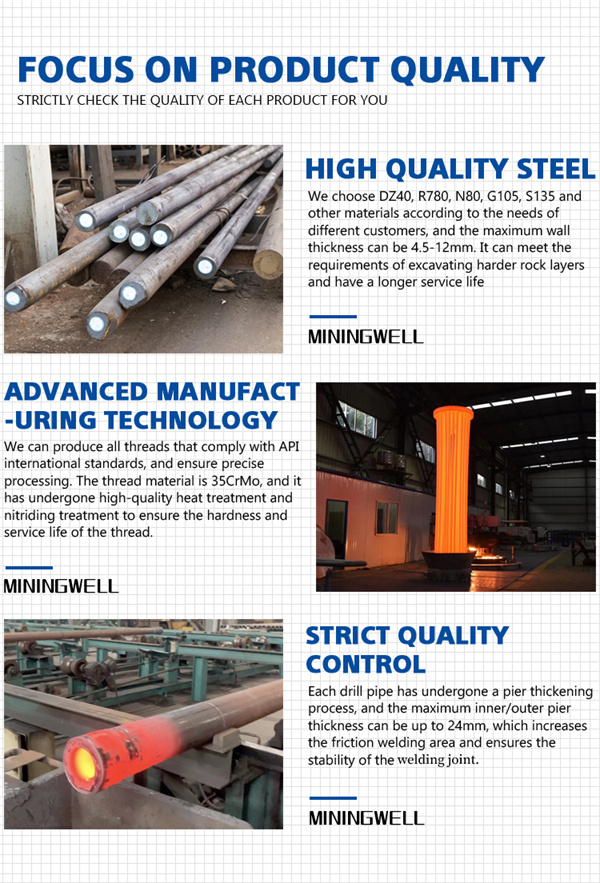

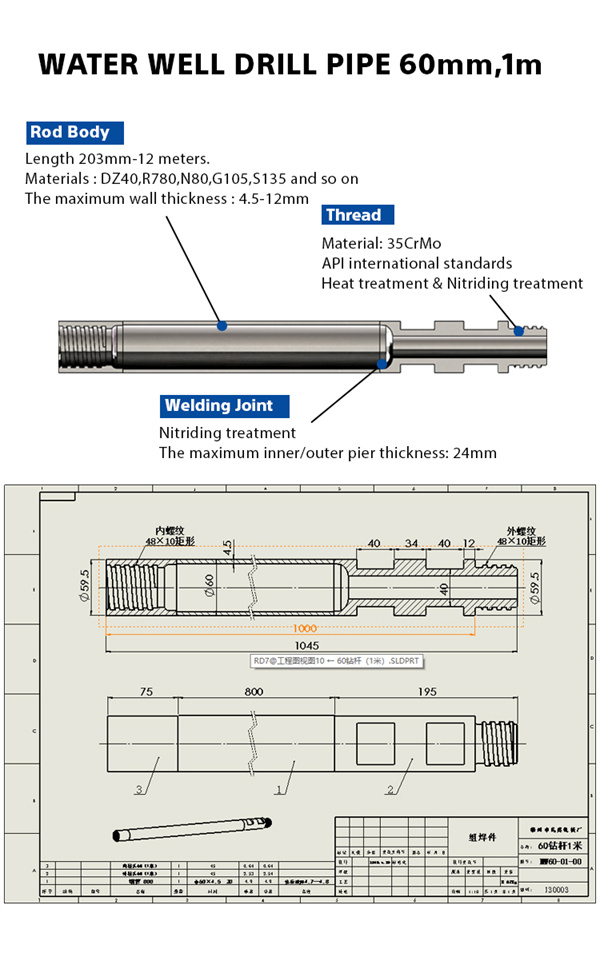

Thread: We can produce all threads that comply with API international standards, and guarantee precision processing. The thread material is 35CrMo, and it has undergone high-quality heat treatment and nitriding treatment to ensure the hardness and service life of the thread.

Rod body: We can supply drill rods with diameters of 42mm-203mm, and the maximum length can be made up to 12 meters. We choose DZ40, R780, G105, S135 and other rod materials according to the needs of different customers and the use scenarios of drill rods, and the wall thickness can be 4.5mm-12mm.

Welding joint: Each drill pipe has undergone a pier thickening process, and the maximum inner/outer pier thickness can be up to 11mm, which increases the friction welding area and ensures the stability of the welding joint.

Advantages and scope of application of friction welding drill pipe

D miningwell is a professional enterprise engaged in the research, production and sales of drilling tools. Today, I will introduce the production advantages and application scope of friction welded drill pipes.

The combination of drill pipe requires welding, and there are various welding methods. Among them, the friction welding drill pipe is very popular among customers in the market. The friction welding process is cold working of the pipe body, which ensures the uniform thickness of the pipe body, the accuracy of the drill pipe, and also enhances the friction welding drill pipe. hardness and toughness.

Friction-welded drill pipe is mainly suitable for drill bits with threaded drills. It has the characteristics of good rotation and low resistance during rotary installation, and it is also relatively simple in the operation process, which is loved by people.

Friction welding drill pipe can be welded with different materials, which improves the quality of the drill pipe, which is different from other welding methods of drill pipe. The application of friction welding technology enhances the flexibility of the friction welded drill pipe and prolongs the service life of the drill pipe. According to the heat treatment of the inside of the drill pipe, the thickness of the weld is thickened and thickened, and the internal strength of the drill pipe is also greatly enhanced.

| 89Type drill pipe(Double buckle) | ||||

| Diameter(mm) | Length(mm) | Thread model | Weight(kg) | Remarks |

| 89 | 1500 | API 2 3/8″ IF | 28 | Nitrogen treatment Jumping-up |

| 89 | 2000 | API 2 3/8″ IF | 34 | |

| 89 | 3000 | API 2 3/8″ IF | 46 | |

| 89 | 6000 | API 2 3/8″ IF | 88 | |

| 102Type drill pipe(Single buckle) | ||||

| Diameter(mm) | Length(mm) | Thread model | Weight(kg) | Remarks |

| 102 | 1500 | API 2 7/8″ IF | 37 | Nitrogen treatment Jumping-up |

| 102 | 2000 | API 2 7/8″ IF | 46 | |

| 102 | 3000 | API 2 7/8″ IF | 64 | |

| 102 | 6000 | API 2 7/8″ IF | 118 | |

| 102Type drill pipe(Double buckle) | ||||

| Diameter(mm) | Length(mm) | Thread model | Weight(kg) | Remarks |

| 102 | 1500 | API 2 7/8″ IF | 38 | Nitrogen treatment Jumping-up |

| 102 | 2000 | API 2 7/8″ IF | 47 | |

| 102 | 3000 | API 2 7/8″ IF | 65 | |

| 102 | 6000 | API 2 7/8″ IF | 119 | |