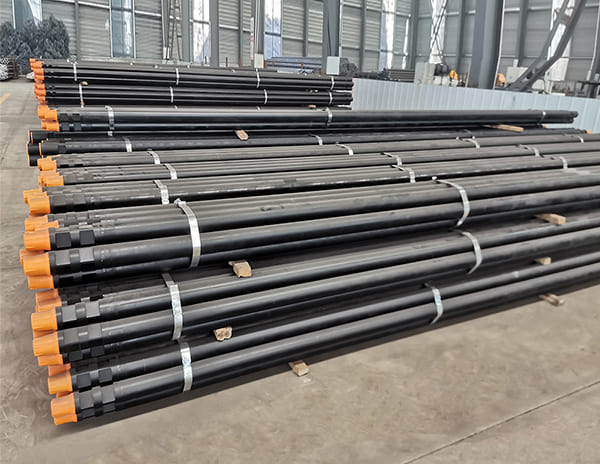

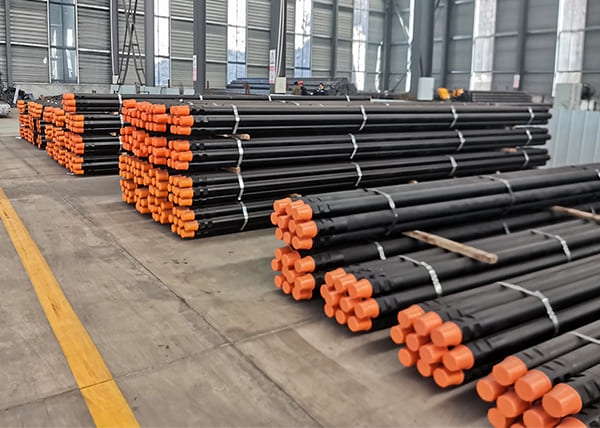

Friction welding drill pipe

D miningwell is a professional enterprise engaged in the research, production and sales of drilling tools.

Application field

Drilling, mining and anchoring in coal mines, mines, construction, water conservancy projects, railways, highways, bridges and tunnels and other industries. In coal mines, it is mainly used for coal mine water exploration, gas exploration, and roadway exploration.

Product advantages

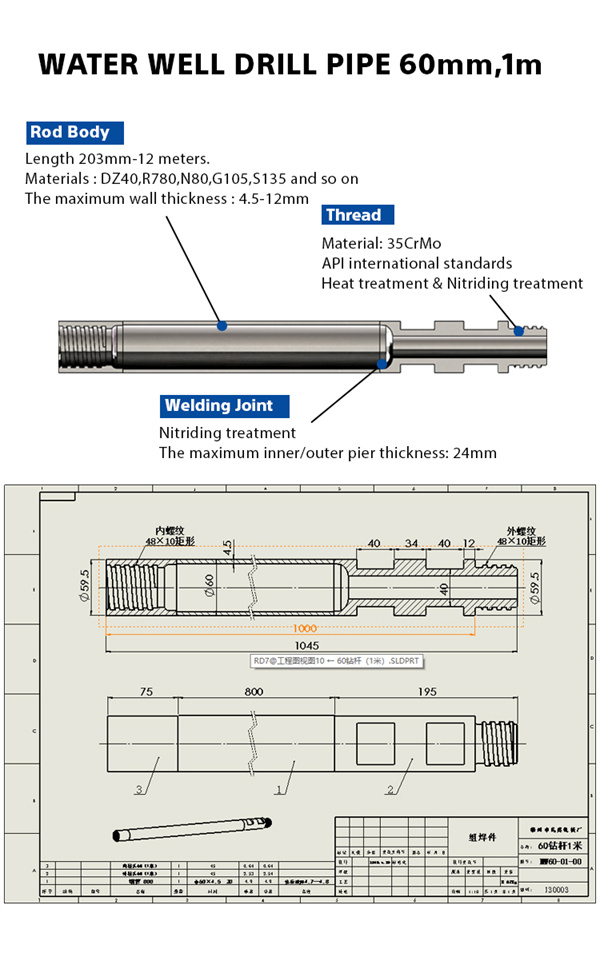

The main body of the drill pipe is made of high-quality geological special alloy steel pipe, and the drill pipe joint is made of high-quality alloy structural steel. The machining accuracy of the products, the production process of friction welding first and then thread processing, ensures the coaxiality standard of multiple connections of drill rods when deep hole drilling. stability, etc.

Connection Type

Buckle type: flat buckle, taper buckle

Flat buckle: ¦µ34.0mm, ¦µ42.0mm, ¦µ50.0mm (drill pipe diameter)

Taper buckle: ¦µ63.5mm, ¦µ73.0mm, ¦µ89.0mm (drill pipe diameter)

Flat buckles are generally used for small diameter geological drill pipes. With the increase of the diameter of the drill pipe, the drilling depth and the torque of the drill pipe will increase accordingly. The drill pipe connected by the taper can ensure the transmission of torque when the drill pipe is working, and it is also more convenient to disassemble. It can also be customized according to the special needs of customers.

Drill match

The diameter difference between the drill pipe and the drill bit is the primary factor to be considered. The diameter difference refers to the difference between the diameter of the drill pipe and the drill bit. The diameter of the drilled hole is caused by the diameter of the drill bit. The diameter of the drill pipe should be smaller than the diameter of the drill bit. During the drilling process, the force on the drill pipe can be reduced to a minimum. There is no clear standard value for the diameter difference. According to our experience, our drill pipe and drill bits are matched as follows: