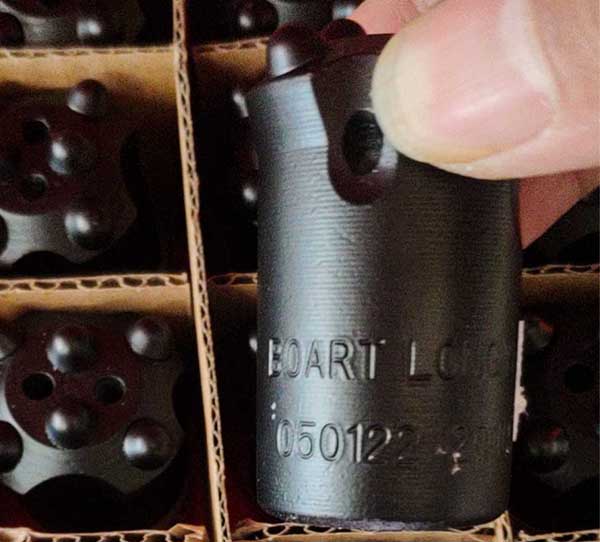

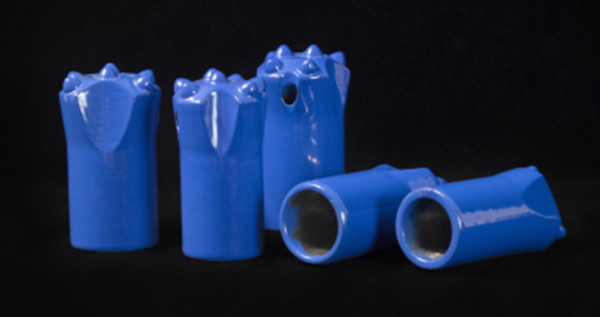

Good Price 36mm 38mm 41mm drill bit button tapered 11degree drill bit prices

The ball-tooth drill bit is composed of cemented carbide column teeth inlaid on the drill bit body. Compared with the chip drill bit, the ball tooth drill bit has free tooth arrangement, and the number and position of the edge and middle teeth can be reasonably determined according to the diameter of the chisel hole and the size of the rock breaking load, and the diameter of the drill bit is not limited. And because it is multi-point crushing, the rock-breaking efficiency is higher, which can effectively eliminate the blind area of rock-breaking and avoid the repeated crushing of cuttings. Its non-grinding life is longer and the regrinding workload is small. It shows high value under the operating conditions of rock trolley and deep hole mining.

When using the tapered button bit and the drill rod, first check whether the drill tail of the tapered drill rod is flat, whether the taper tip and the taper hole meet the requirements, whether the cutting edge of the tapered button bit is damaged, whether the water hole is not unblocked, and whether the air pressure water Whether the pressure is enough, the tapered button bit is strictly forbidden to collide with the alloys between the tapered button bits. When drilling holes, it should be noted that the wind must be light and light, that is, the wind pressure should be drilled with a small amount first, and then the wind pressure can be gradually adjusted to normal after the drilling is stable. When withdrawing the drill, try to reverse the drill and avoid forcibly knocking and pulling as much as possible, so as not to damage the tapered button bit or the drill rod, resulting in early scrapping.