High Quality And Strength Water Well Dth Drill Pipe

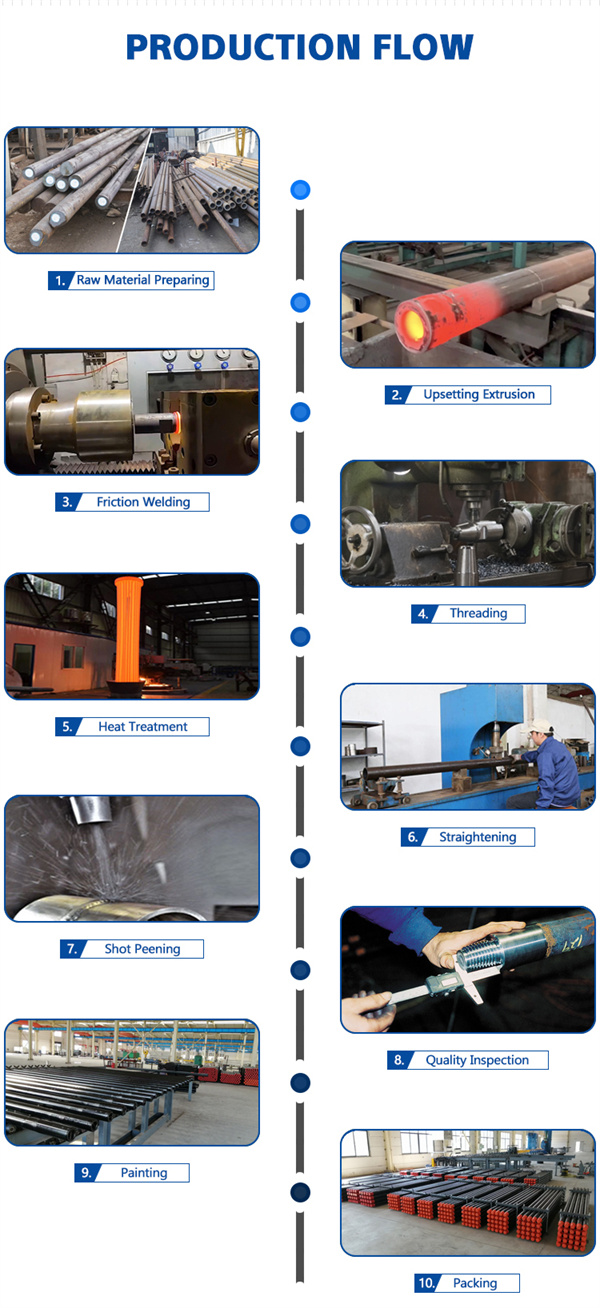

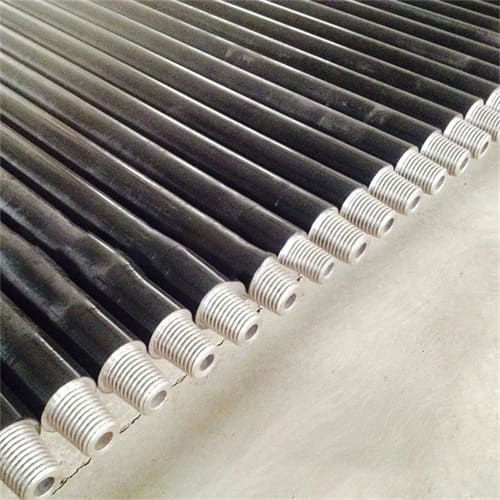

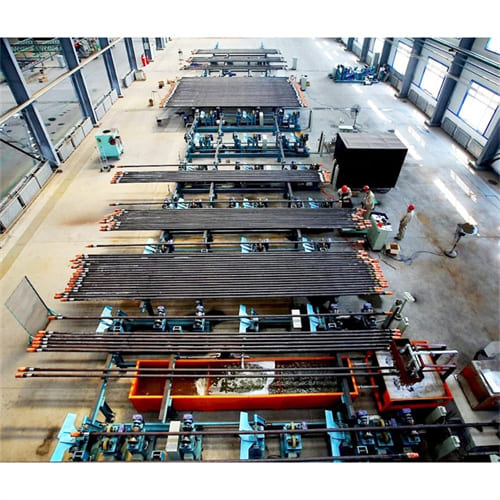

D Miningwell equips all rock drilling equipment with high-quality friction welded drill rods. The threads, rod bodies and welded joints of the drill pipes have been rigorously processed.

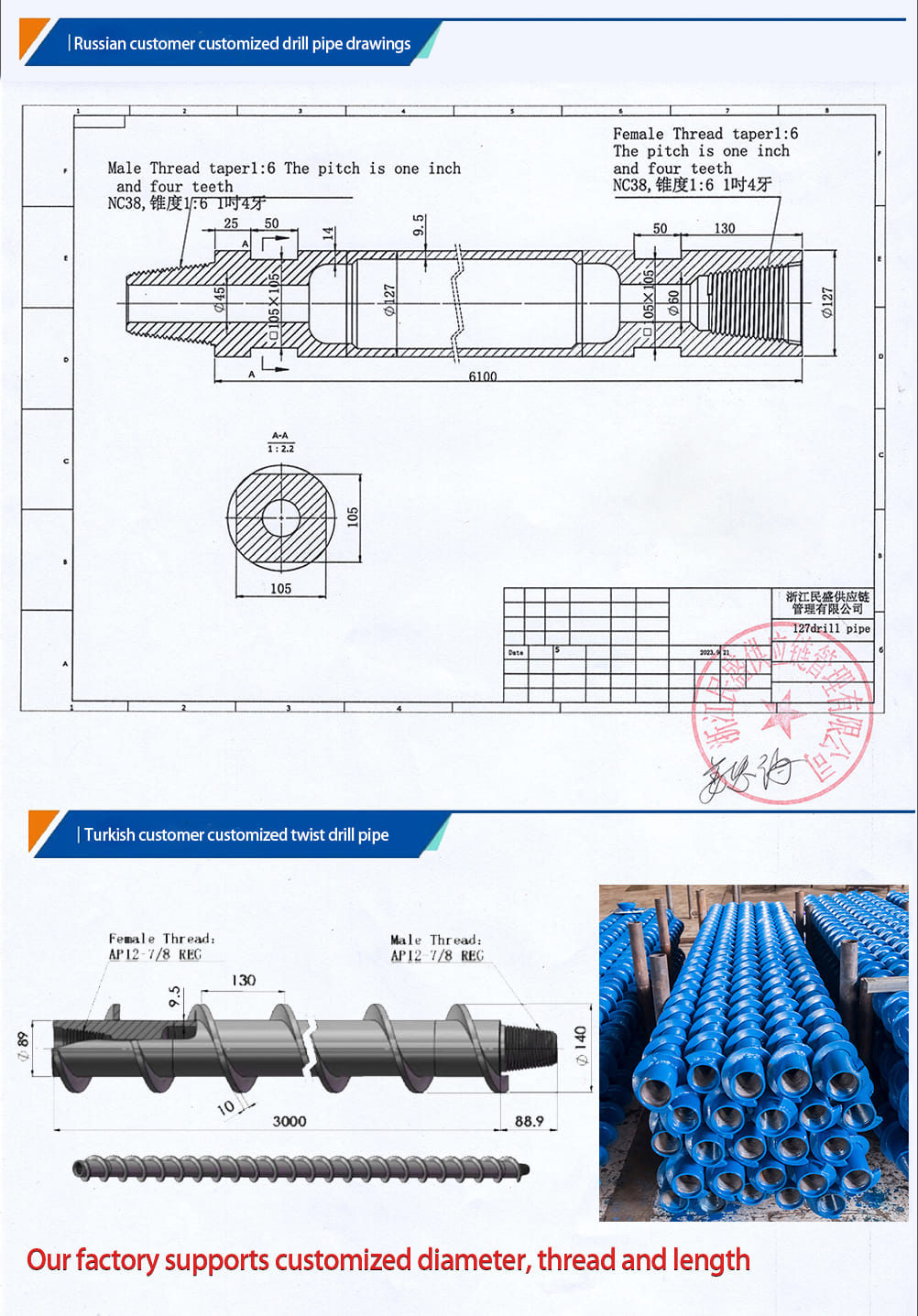

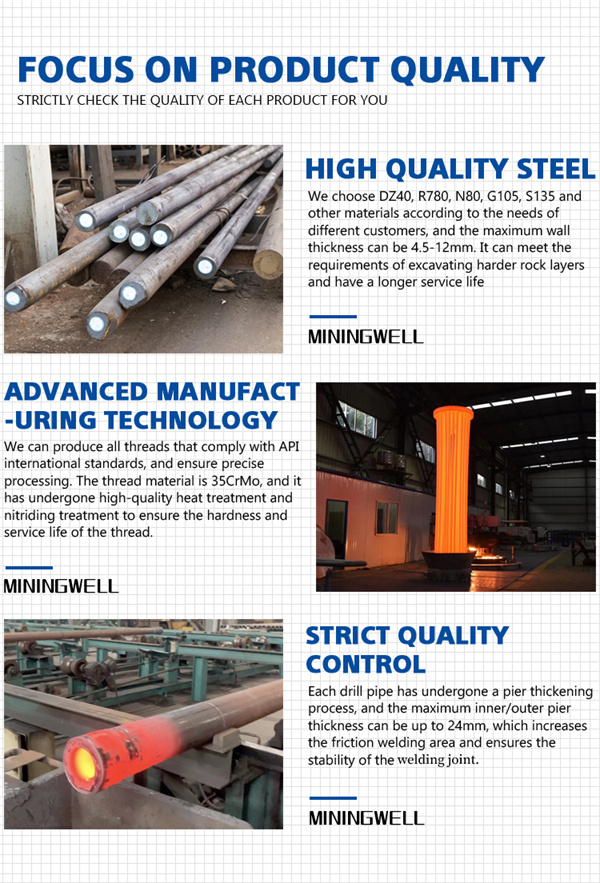

Thread: We can produce all threads that comply with API international standards, and guarantee precision processing. The thread material is 35CrMo, and it has undergone high-quality heat treatment and nitriding treatment to ensure the hardness and service life of the thread.

Rod body: We can supply drill rods with diameters of 42mm-203mm, and the maximum length can be made up to 12 meters. We choose DZ40, R780, G105, S135 and other rod materials according to the needs of different customers and the use scenarios of drill rods, and the wall thickness can be 4.5mm-12mm.

Welding joint: Each drill pipe has undergone a pier thickening process, and the maximum inner/outer pier thickness can be up to 24mm, which increases the friction welding area and ensures the stability of the welding joint.

How to maintain friction welding drill pipe on time during decoration and construction

When friction-welded drill pipe and twist drill supporting facilities are used, the twist drill should generally exceed the diameter of the drill pipe, and the conditions of the drilling machine and drill pipe should be paid attention to at any time during the drilling process. In the event of sticking, wheel locking, etc., the drilling should be stopped immediately or drilled back slowly to ensure that the drill pipe is not bent and deformed. When the drill pipe is in natural ventilation or pressure test, it is necessary to make sure that the drill pipe is connected by a gap when drilling. The drill pipe has sealing properties. When the friction welding drill pipe is maintained for a long time, such as O-rings, pay attention to the use of the hydraulic seals. In the event of damage, corrosion, etc., the hydraulic seals should be replaced immediately. . After the drilling is carried out, the maintenance and removal of the hydraulic seals are carried out. When the rod is drilled, it should be manually connected properly to ensure mutual cooperation. It is not possible to use the drilling machine to drill immediately to avoid harm to the drill pipe.

| Model | Diameter (mm) | Thickness(mm) | Thickening type | Length(mm) | Thread | Board shank slot |

| 1 | 76 | 5-8mm | IU | 1000/ 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 2 3/8 API REG | Double buckle Single buckle |

| 2 | 89 | 6-9.35mm | IU | 1000/ 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 2 3/8 IF | Double buckle Single buckle |

| 3 | 102 | 7-8.38mm | IU/IEU | 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 2 7/8 IF 3 1/2 REG | Double buckle Single buckle |

| 4 | 114 | 6-9.35mm | IU | 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 2 7/8 IF 3 1/2 IF/REG | Double buckle Single buckle |

| 5 | 127 | 9mm | IU | 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000 | 3 1/2 IF | Double buckle Single buckle |

| 6 | 140 | 8-12mm | IU | 3000/ 4500/ 5000/ 6000 | 4 1/2 REG or 4FH | Double buckle Single buckle |