Hot selling in Chile factory wholesale 34mm taper button bit 7/8/11/12 degree for hard rock drilling

Taper bits, especially Tapered button bits are the most popular tapered drill bits with a wide selection of head diameters from 26mm to 48mm. With carbide buttons hot pressed on the bit skirts, tapered button bits have a good drilling performance and are excellent in longevity.

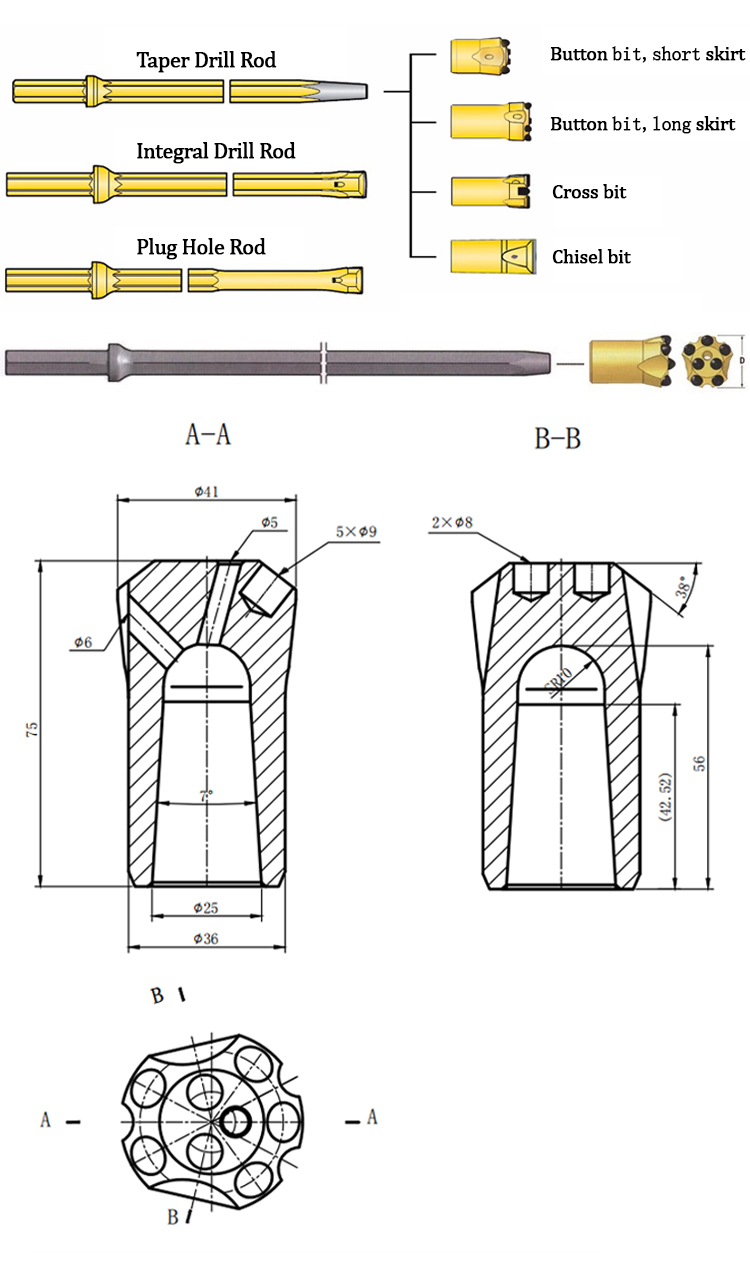

We manufacture various tapered button bits in different degrees as below:

Bit diameter: 26mm to 60mm;

Tapered degree: 4°, 6°, 7°, 11°, 12°;

Shank sizes: Hex. 19mm, Hex, 22mm and Hex. 25mm;

Carbide type: Chisel type, Cross type, Button type.

The rock drilling tool is a tool for human beings to conquer rock and ore. Its structure is composed of a slender hollow drill pipe and a drill bit inlaid with rock drilling carbide. In the process of rock drilling, under the conditions of severe wear and tear of rock ores and erosion and corrosion of high-pressure water flow (or compressed air) and pit water, the drill rod and drill bit are subjected to various forces such as tension, compression, bending, and torsion, and the rock drill is 2000 per minute. The high frequency impact of ~3000 times, and the impact energy per impact is as high as 25J~500J, so the drill rod and drill bit often fail by stress corrosion fatigue fracture, and their service life is generally only ten minutes to dozens of hours. Therefore, rock drilling tools are a large number of consumable tools that are indispensable in basic industries with harsh stress conditions, short service life and high technical content among all human steel tools.

1. The choice of mine tapered button bit

According to the nature of the rock, choose the appropriate tapered button bit for cemented carbide mines. Generally speaking, for rock with high hardness, tapered bit provided by alloy with relatively low hardness is selected, otherwise, tapered bit of alloy with relatively high hardness is selected. For extremely hard rock, if the power of the rock drill is high, the three-blade or cross tapered bit can be used. At this time, in order to facilitate unloading, the taper hole of the tapered button bit can be selected at 11° or 12°. For medium-hard rock with good integrity, in order to improve work efficiency and reduce costs, the tapered button bit can be selected.

2. Selection of drill rod

The drill rod should ensure that there is only enough mating surface with the tapered button bit. Under normal circumstances, the depth of the tapered drill rod inserted into the tapered button bit should be ≥25mm, and the contact surface should be as large as possible, and the minimum should not be less than 60%. Therefore, try to use tapered rods whose taper tips are machined by machining. The drill rod used in conjunction with the tapered button bit should be straight to the naked eye, and the impact end face of the drill tail should be flat.

Whether it is a tapered bit or a tapered drill rod, the water hole should be kept clear.

2. Use

When using the tapered button bit and the drill rod, first check whether the drill tail of the tapered drill rod is flat, whether the taper tip and the taper hole meet the requirements, whether the cutting edge of the tapered button bit is damaged, whether the water hole is not unblocked, and whether the air pressure water Whether the pressure is enough, the tapered button bit is strictly forbidden to collide with the alloys between the tapered button bits. When drilling holes, it should be noted that the wind must be light and light, that is, the wind pressure should be drilled with a small amount first, and then the wind pressure can be gradually adjusted to normal after the drilling is stable. When withdrawing the drill, try to reverse the drill and avoid forcibly knocking and pulling as much as possible, so as not to damage the tapered button bit or the drill rod, resulting in early scrapping.

| Technical Parameters | ||||||

| DIAMETER | BUTTONS | FLUSHING | CARBIDE | FACE | ||

| MM | IN | GAUGE NO/ SIZE | FRONT NO/ SIZE | HOLE | PROFILE | PROFILE |

| 32 | 1 1/4″ | 5×7 | 2×7 | IF1G | Parabolic | Flat |

| 36 | 1 13/32″ | 5×8 | 2×7 | 2F1G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 1F2G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 2F 1G | Conical | Flat |

| 38 | 1 1/2″ | 5×9 | 2×7 | 2F1G | Conical | Flat |

| 40 | 1 9/16″ | 5×9 | 2×8 | 2F 1G | Conical | Flat |

| 41 | 1 5/8″ | 5×9 | 2×8 | 2F1G | Conical | Flat |

| 41 | 1 5/8″ | 5×9 | 2×8 | 2F 1G | Parabolic | Flat |