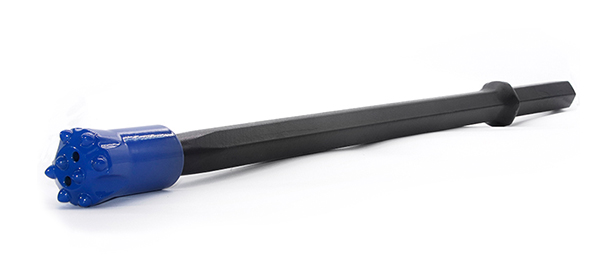

Home » Taper rod » How to choose a tapered drill pipe?

Content

There are many factors to consider when choosing a tapered drill rod. First, we need to see the material of the drill pipe and its shape and size. At the same time, we also need to consider the strength of the rock drill, the strength and hardness of the rock. If the hardness of the rock is relatively large, we need to choose a higher power rock drill and a tapered drill rod of good quality. In choosing tapered rod.

When drilling, we must first understand the diameter of the drilling tool, and the depth of the rock hole is also a factor that cannot be ignored. The drill rod should not only adapt to the drilling hole, but also choose a tapered pipe that is consistent with the interface.

| Technical Parameters | ||

| Length (L) | Weight | |

| mm | foot/inch | approx, kg |

| 800 | 2″ | 2.8 |

| 1220 | 4′ | 4.2 |

| 1525 | 5′ | 5.3 |

| 1600 | 5’3″ | 5.3 |

| 1830 | 6′ | 5.9 |

| 2000 | 6’6% | 6.6 |

| 2435 | 81 | 7.7 |

| 2435 | 8′ | 7.9 |

| 3200 | 10’6° | 10.3 |

| 3655 | H’117/8″ | 11.7 |

| 4000 | 13’V/21 | 12.8 |

| 4800 | 159, | 15.2 |

| 5600 | 18’4 ‘ | 17.6 |

| 6400 | 21′ | 20 |

| 7200 | 23″ | 22.4 |

| 8000 | 26*3″ | 24.9 |

Inquiry

More Taper rod