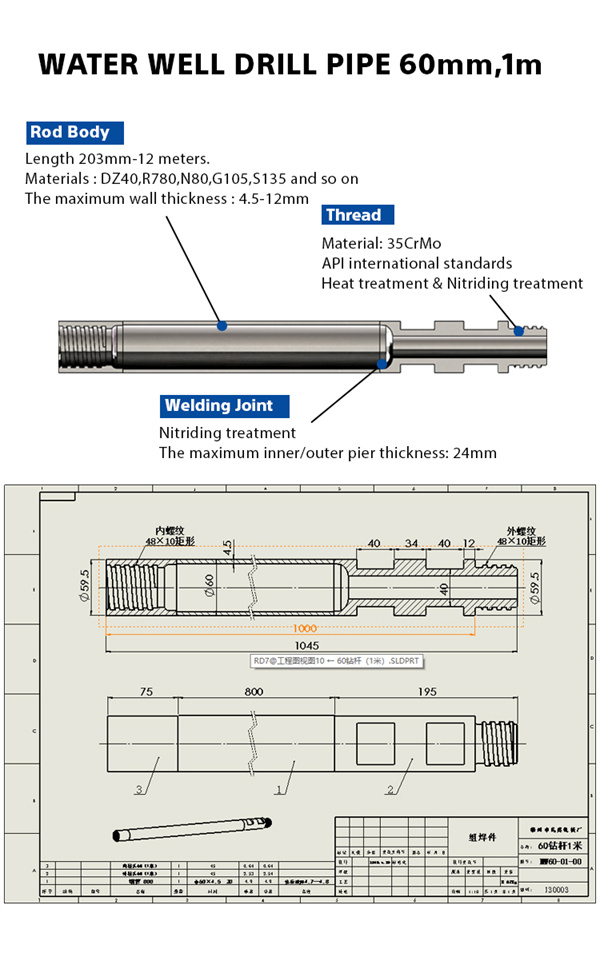

When friction-welded drill pipe and twist drill supporting facilities are used, the twist drill should generally exceed the diameter of the drill pipe, and the conditions of the drilling machine and drill pipe should be paid attention to at any time during the drilling process. In the event of sticking, wheel locking, etc., the drilling should be stopped immediately or drilled back slowly to ensure that the drill pipe is not bent and deformed. When the drill pipe is in natural ventilation or pressure test, it is necessary to make sure that the drill pipe is connected by a gap when drilling. The drill pipe has sealing properties. When the friction welding drill pipe is maintained for a long time, such as O-rings, pay attention to the use of the hydraulic seals. In the event of damage, corrosion, etc., the hydraulic seals should be replaced immediately. . After the drilling is carried out, the maintenance and removal of the hydraulic seals are carried out. When the rod is drilled, it should be manually connected properly to ensure mutual cooperation. It is not possible to use the drilling machine to drill immediately to avoid harm to the drill pipe.