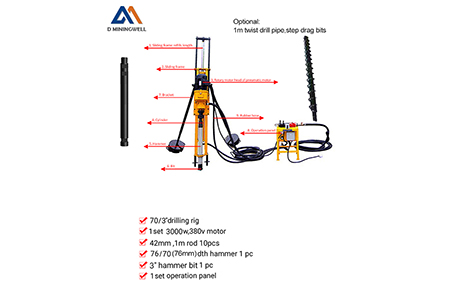

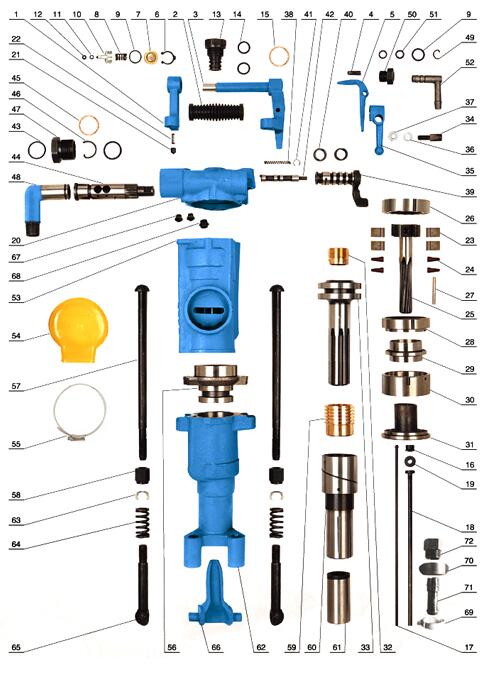

HQD70 Electric Down-the-Hole Drill: Efficient and Versatile Solution for Various Drilling Projects

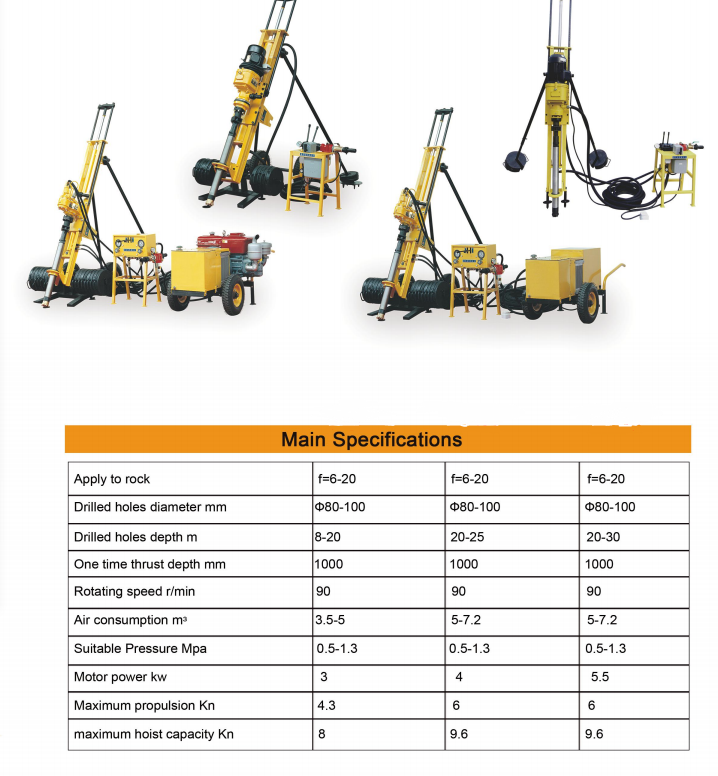

The HQD70 Electric Down-the-Hole Drill is a newly designed, highly efficient and widely applicable rock drilling equipment. It serves well in small and medium-sized mines, as well as in transportation, national defense, water conservancy, and stonework projects. Especially suitable for uneven and rugged terrains where other drill rigs can’t operate normally. With a simple structure, easy operation, low cost, and energy-saving features, it can drill both vertical and horizontal blast holes. Its low center of gravity and good disassembling property make relocation and transportation extremely convenient. The drill has a low air consumption of the impactor, requiring a small displacement air compressor, which is economical. The rotary reducer has a large torque and shows good reliability under strong vibration and high load. The electrical system has overload and phase loss protection functions, ensuring stable and reliable operation. The propulsion system is equipped with a pressure reducing valve to adjust the propulsion force according to different rock conditions for the best drilling effect.