1. Using its single power to drive the screw air compressor and drilling rig hydraulic system at the same time, compared with the separated DTH drilling rig, the comprehensive fuel consumption and energy saving are 35%, and the maintenance cost is reduced by 50%;

2. The core hydraulic components are imported from Europe. The reliable hydraulic system greatly reduces the workload of system maintenance and is convenient and practical;

3. Powerful two-speed hydraulic traveling mechanism, strong off-road capability, and large torque swing motor can easily deal with drill stuck;

4. The two-stage dry dust collection device is environmentally friendly and helps improve production efficiency; the integrated technology solves the problems of moving and long-distance management of air compressors in engineering and mining.

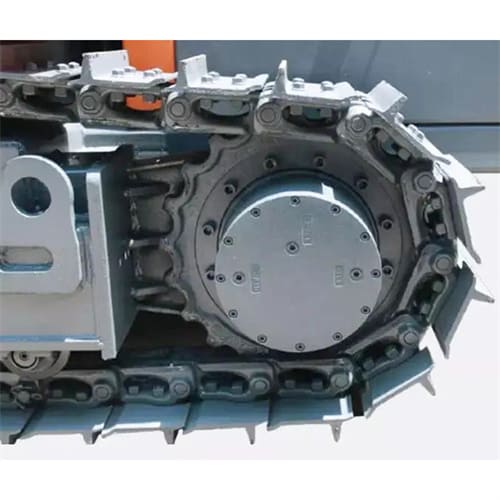

5. Equipped with standard plunger motor and international engineering machinery walking track, it is more powerful for climbing, more reliable in quality and high in walking efficiency.

.jpg)