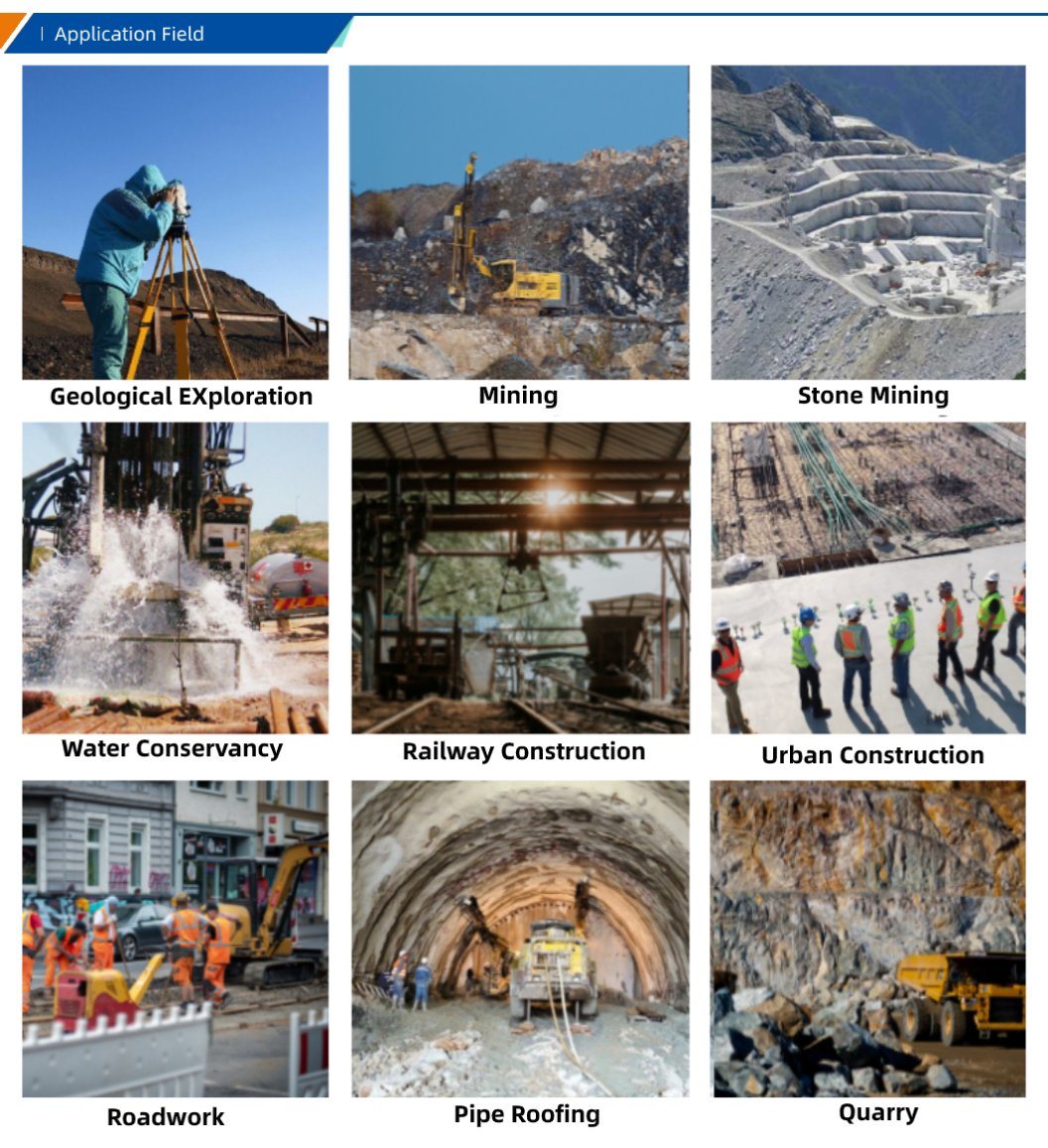

MWYX series products have the characteristics of high efficiency, environmental protection, energy saving and safety.

Automatic drill change and powerful off-road performance reduce rig assist time. The large displacement high pressure screw air compressor makes the slag discharge completely, which is more conducive to the substantial increase of the rock drilling speed and reduces the consumption of the drilling rig. The powerful propulsion and rotation design solves the problem of sticking in complex rock formations on the basis of satisfying high-speed rock drilling.

The standard two-stage dry dust collector and optional wet dust collector of the drilling rig not only meet the environmental protection needs of mines and operators, but also greatly reduce the pollution of dust to the equipment itself.

The single engine of the drilling rig drives the screw air compressor and hydraulic system at the same time, which reduces the total power of the diesel engine of the split drilling rig by about 35% and the maintenance cost by 50%.

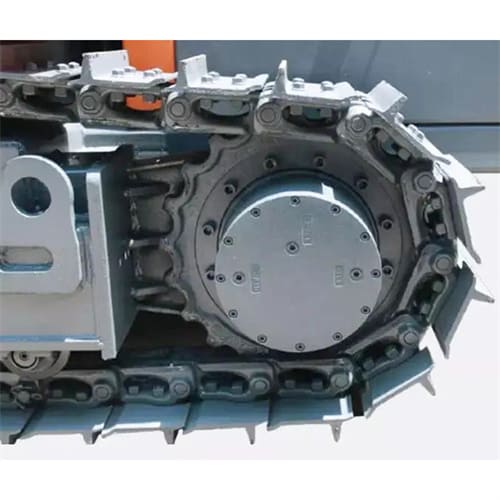

The drilling rig is equipped with the crawler leveling function, which makes the center of gravity of the drilling rig more stable up and down the slope, and the powerful operation capacity reduces the number of equipment and personnel required in the mine.