Well Drilling Bits Manufacturers and Suppliers

D Miningwell dth hammer is connected with dth drill bit for drilling engineering. D Miningwell uses high-quality steel, alloy steel as raw materials, adopts special heat treatment process and advanced cemented carbide inserting technology, so that dth hammers bits can function well even on hard rock formations, and at the same time save energy.

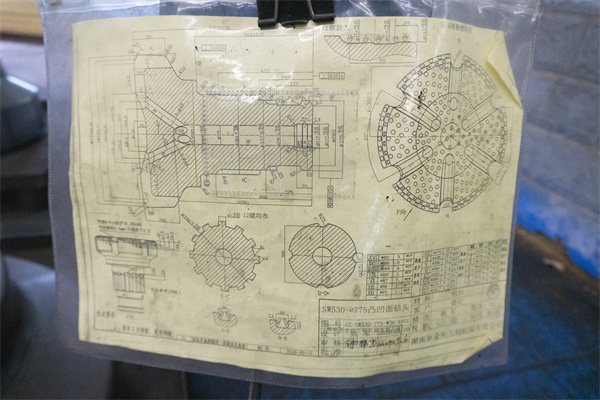

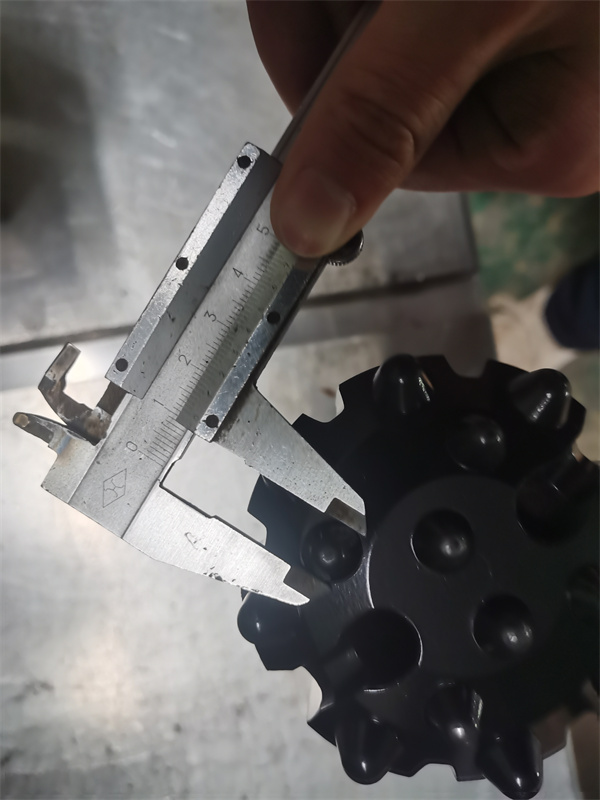

The Down the hole drill bit is used together with the down-the-hole hammer, and the drilling operation is carried out by cooperating with the hammer through the spline. Manufactured with high-quality steel and cemented carbide as raw materials, after a special heat treatment process, the button bit can meet the requirements of digging in rock formations with strong hardness, and can minimize the loss in the process of energy transmission. The tooth force is even and it is not easy to drop and take off the teeth, so that the impact energy can be concentrated on the rock to achieve the purpose of efficient tunneling. Mainly used in geological exploration, coal mines, water conservancy and hydropower, roads, railways, bridges, construction, etc.

Advantages of D Miningwell DTH Bits

1. Long life of dth bits: the wear ratio of cemented carbide is more than 10-20 times that of similar products, so the life is greatly extended;

2. High drilling efficiency: the hard alloy has high hardness and wear resistance, and the drill bit can always be kept sharp, thus greatly increasing the tooth feeding speed;

3. Wide range of application: Practice has proved that the drill bit is suitable for drilling in medium-hard formations such as carbonate rock, limestone, chalk, clay rock, siltstone, and sandstone.

4. Due to the fast drilling speed and long service life, the times of tripping and tripping are less, and the drilling cost is greatly reduced, which has excellent cost performance.

| Technical Parameters | |||||

| Model: | Gauge buttons(mm) | Front buttons(mm) | Tail shank diameter(mm) | Port holes | Weight(KG) |

| CIR76-76 | φ12*5 | φ12*3 | φ43 | 2 | 2.1 |

| CIR90-90 | φ14*6 | φ13*2+φ12*2 | φ53.5 | 2 | 3.7 |

| CIR90-110 | φ14*6 | φ13*3+φ12*3 | φ53.5 | 3 | 4.6 |

| CIR90-130 | φ14*7 | φ13*3+φ12*4 | φ53.5 | 3 | 6 |

| CIR110-110 | φ14*6 | φ13*3+φ12*3 | φ64 | 3 | 6 |

| CIR110-130 | φ14*7 | φ13*3+φ12*4 | φ64 | 3 | 7.4 |

| CIR110-150 | φ14*8 | φ14*3+φ13*6 | φ64 | 3 | 9.6 |

| CIR110-170 | φ15*9 | φ14*6+φ13*10 | φ64 | 3 | 12.3 |

| CIR110-200 | φ15*9 | φ14*6+φ13*12 | φ64 | 3 | 16.5 |

| CIR150-150 | φ16*9 | φ14*6+φ14*4 | φ89.5 | 3 | 14.8 |

| CIR150-175 | φ16*9 | φ14*6+φ14*5 | φ89.5 | 3 | 19 |

| CIR170-175 | φ16*9 | φ14*6+φ14*5 | φ102 | 3 | 21 |

| CIR170-185 | φ16*9 | φ14*6+φ14*6 | φ102 | 3 | 21.8 |

| Technical Parameters | |||||||

| Model: | Head diameter: | Shank length: | Spline: | Port holes: | Gauge buttons: | Front buttons: | Weight: |

| DHD25A-76 | 76 | 174 | 6 | 2 | φ14mm*6 | φ11mm*4 | 3.2kg |

| DHD35A-90 | 90 | 180 | 8 | 2 | φ14mm*6 | φ12mm*5 | 4.7kg |

| DHD35A-100 | 100 | 180 | 8 | 2 | φ14mm*6 | φ12mm*5 | 4.8kg |

| DHD340-108 | 108 | 209 | 8 | 2 | φ16mm*7 | φ14mm*6 | 7.85kg |

| DHD340-130 | 130 | 209 | 8 | 2 | φ16mm*8 | φ14mm*4+φ13mm*3 | 8.88kg |

| DHD350-140 | 140 | 260 | 8 | 2 | φ18mm*7 | φ15mm*4+φ14mm*3 | 15.8kg |

| DHD350-152 | 152 | 260 | 8 | 2 | φ18mm*8 | φ14mm*8 | 17kg |

| DHD350-178 | 178 | 260 | 8 | 2 | φ18mm*8 | φ16mm*6+φ14mm*5 | 20.4kg |

| DHD360-154 | 154 | 308.5 | 8 | 2 | φ18mm*8 | φ16mm*4+φ15mm*4 | 22.5kg |

| DHD360-178 | 178 | 308.5 | 8 | 2 | φ18mm*8 | φ16mm*6+φ15mm*5 | 26.1kg |

| DHD360-203 | 203 | 308.5 | 8 | 2 | φ18mm*10 | φ16mm*8+φ15mm*6 | 30.4kg |

| DHD380-203 | 203 | 350 | 10 | 2 | φ18mm*10 | φ18mm*4+φ16mm*10 | 48.5kg |

| DHD380-254 | 254 | 350 | 10 | 2 | φ18mm*12 | φ18mm*12+φ16mm*8 | 62.4kg |