What is Product Customization? DTH Drill Tools

May 13, 2023

Question 1:

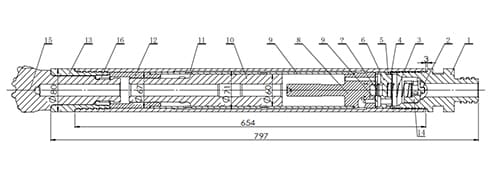

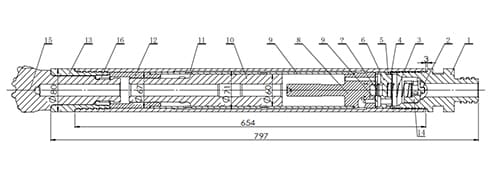

During this communication with the customer, he pointed out that the width of the wrench slot next to the thread of our CIR90A DTH hammer is too narrow to meet their requirements, as shown in the figure below:

The customer requires a width of 32CM and a height of 57CM, as shown below:

.jpg)

The difficulty here is that our conventional DTH hammer do not meet customer requirements. If the production is customized according to the customer's requirements, the production time will be longer and the cost will be higher.

Finally, according to the customer's requirements, we produced customized CIR90 DTH hammer for him, and the customer was very satisfied.

Question 2:

Due to the very high hardness of the rock used by the customer (quartzite), our ordinary drill bits have been broken and lost carbide. As shown below:

.jpg)

After communication with the customer, we finally decided to customize the drill bit suitable for his rock hardness, increase the amount of carbide in the drill bit, and rearrange the position of the carbide.So that the wear resistance and quality of the drill have been greatly improved, and the customer was very satisfied after receiving it.

Good products not only require high-quality raw materials, but also advanced production technology. Before customizing DTH hammer for a customer, we will first make a production drawing for him according to the customer's requirements, so that he can fully understand our ideas.

In the production process of drill bits and drill rod pipes, our biggest advantage is the mature friction welding process and advanced heat treatment process.

This makes our products always at a high quality level.

During this communication with the customer, he pointed out that the width of the wrench slot next to the thread of our CIR90A DTH hammer is too narrow to meet their requirements, as shown in the figure below:

The customer requires a width of 32CM and a height of 57CM, as shown below:

.jpg)

The difficulty here is that our conventional DTH hammer do not meet customer requirements. If the production is customized according to the customer's requirements, the production time will be longer and the cost will be higher.

Finally, according to the customer's requirements, we produced customized CIR90 DTH hammer for him, and the customer was very satisfied.

Question 2:

Due to the very high hardness of the rock used by the customer (quartzite), our ordinary drill bits have been broken and lost carbide. As shown below:

.jpg)

After communication with the customer, we finally decided to customize the drill bit suitable for his rock hardness, increase the amount of carbide in the drill bit, and rearrange the position of the carbide.So that the wear resistance and quality of the drill have been greatly improved, and the customer was very satisfied after receiving it.

Good products not only require high-quality raw materials, but also advanced production technology. Before customizing DTH hammer for a customer, we will first make a production drawing for him according to the customer's requirements, so that he can fully understand our ideas.

In the production process of drill bits and drill rod pipes, our biggest advantage is the mature friction welding process and advanced heat treatment process.

This makes our products always at a high quality level.

.png)