Analysis of Taper Drill Pipe Materials

Dec 19, 2024

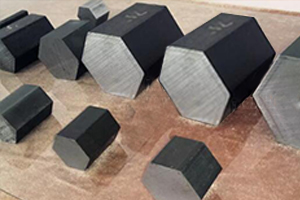

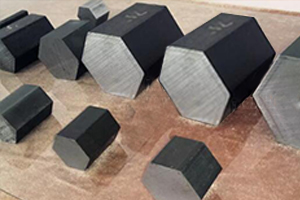

Taper drill pipes can be divided into two types according to their diameter: H22 drill pipe and H25 drill pipe. According to its taper, it can be divided into 7 ° 11 ° 12 ° drill pipe, of which 11 ° H22 drill pipe is the most popular in South America and Africa. 7°, 11°H22 and H25 drill pipe are popular in Russia and Central Asia. Drill pipe lengths range from 0.5m-5m and can usually be customized according to customer requirements.

High-quality taper drill pipes require the following:

1. High fatigue strength and toughness

2. High wear resistance and resistance to permanent deformation

3. Precision tolerances (for automated manufacturing processes)

4. Uniform response to heat treatment

5. Uniform straightness (no straightening required)

International famous brands use Sanbar20, Sanbar21, Sanbar61, Sanbar64, these four grades of standard steel.

.jpg)

The taper drill pipe materials commonly used in China are: 40Si, 55SiMnMo, 23CrNi3MoA. The treated drill pipe through the advanced heat treatment technology and carburizing technology of our factory can meet the Sanbar standards of the internationally renowned brand, and its quality is close to the authenticity. Exported to home and abroad, deeply loved by customers.

High-quality taper drill pipes require the following:

1. High fatigue strength and toughness

2. High wear resistance and resistance to permanent deformation

3. Precision tolerances (for automated manufacturing processes)

4. Uniform response to heat treatment

5. Uniform straightness (no straightening required)

International famous brands use Sanbar20, Sanbar21, Sanbar61, Sanbar64, these four grades of standard steel.

| Sanbar 20 | A high-strength chromium-molybdenum steel with high fatigue strength and excellent wear resistance in the as-rolled condition.The maximum permissible decarburization depth is 0.20 mm (0.008 in.) on the outer surface and 0.10 mm (0.004 in.) on the inner surface. |

| Sanbar 23 | An air-hardening, high chromium-molybdenum alloy steel with good response to surface induction hardening and suitable for carburizing. It has high fatigue strength and wear resistance in the case-hardened condition.The maximum permissible decarburization depth is 0.30 mm (0.012 in.) on the outer surface and 0.20 mm (0.008 in.) on the inner surface. |

| Sanbar 61 | A high-strength silicon steel with good toughness and impact resistance in the as-rolled condition.The maximum permissible decarburization depth is 0.30 mm (0.012 in.) on the outer surface and 0.10 mm (0.004 in.) on the inner surface. |

| Sanbar 64 | An air-hardening, high nickel alloy steel with good response to carburizing. It has excellent fatigue strength and wear resistance in the case hardened condition.The maximum permissible decarburization depth is 0.30 mm (0.012 in.) on the outer surface and 0.20 mm (0.008 in.) on the inner surface. |

.jpg)

The taper drill pipe materials commonly used in China are: 40Si, 55SiMnMo, 23CrNi3MoA. The treated drill pipe through the advanced heat treatment technology and carburizing technology of our factory can meet the Sanbar standards of the internationally renowned brand, and its quality is close to the authenticity. Exported to home and abroad, deeply loved by customers.

.jpeg)

.jpg)

.png)