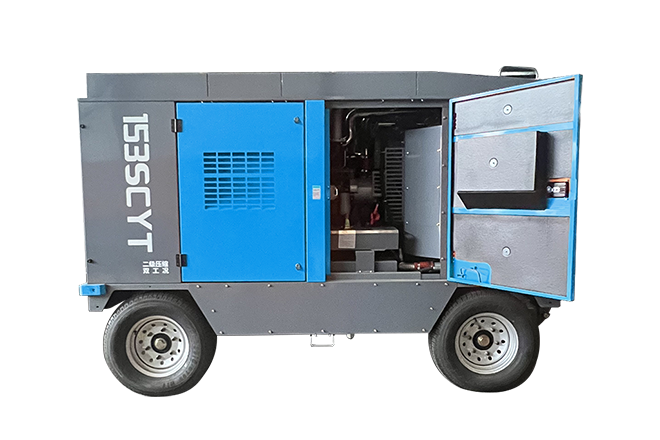

265 SCYT Portable Diesel Air Compressor

Brand Name: D miningwell

Certification: CE, ISO

Minimum Order Quantity: 1 set

Packaging Details: 40HQ-20GP

Delivery Time: 15-20 days

Payment Terms: L/C, T/T, Western Union

265SCYT diesel-driven screw air compressor plays an important role in many fields and has outstanding advantages. In mining, its high-pressure output is suitable for high-pressure down-the-hole impactor rock drilling and deep hole slag and mud removal, and the increased exhaust volume at low pressure can supply air for mine support equipment. In engineering construction, dual-pressure output can also meet the air source needs of different stages and different equipment.

Certification: CE, ISO

Minimum Order Quantity: 1 set

Packaging Details: 40HQ-20GP

Delivery Time: 15-20 days

Payment Terms: L/C, T/T, Western Union

265SCYT diesel-driven screw air compressor plays an important role in many fields and has outstanding advantages. In mining, its high-pressure output is suitable for high-pressure down-the-hole impactor rock drilling and deep hole slag and mud removal, and the increased exhaust volume at low pressure can supply air for mine support equipment. In engineering construction, dual-pressure output can also meet the air source needs of different stages and different equipment.

.jpg)