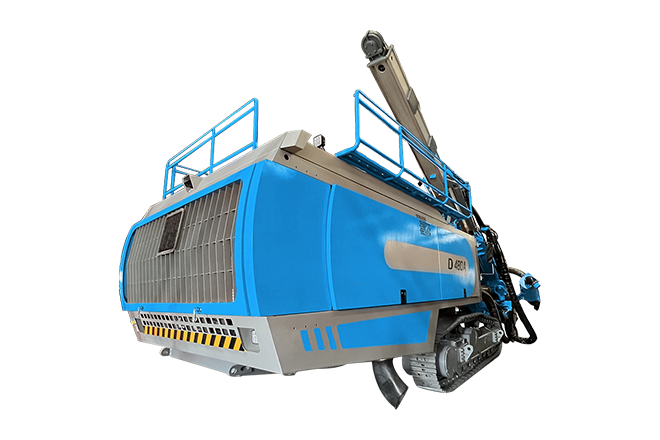

1.Servicing the Surface Iron Mine Drill Rigs DMiningwell D480A is easy with access to all key components such as the engine, fluid levels and compressor through large panel doors located at ground level for maintenance when needed.

2.The DMiningwell D480A surface drill rigs’ cabs have been redesigned to provide operators maximum comfort with single-lever drilling controls, digital gauges, and superior views of drilling operation.

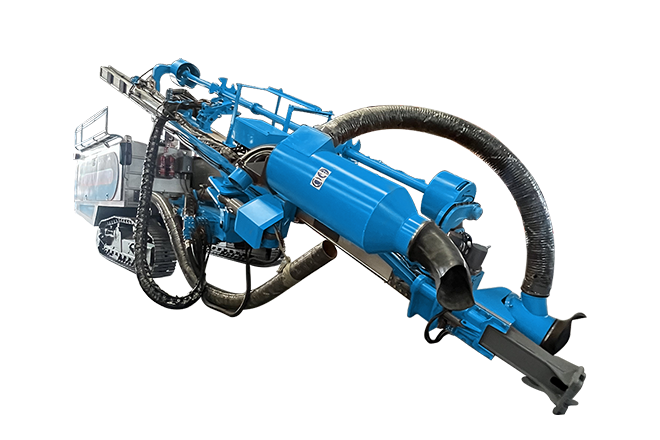

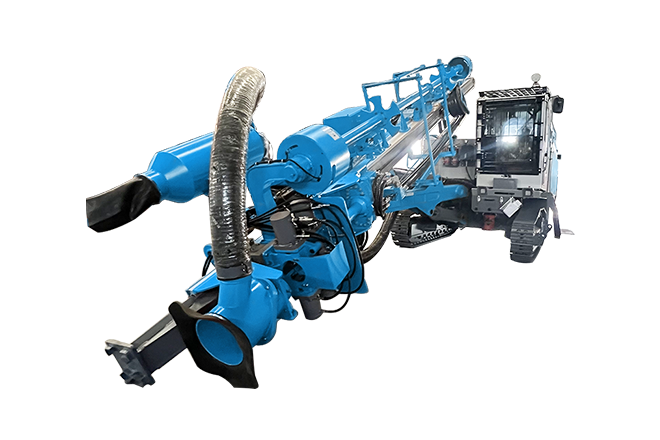

3.DMiningwell D480A Heavy automatic integrated DTH surface Drill Rigs widely used in hole diameter range at φ178‒230 mm. And it optimum hole diameter is φ178mm.

4.DMiningwell D480A widely used in iron mine, gold mine, other kinds of open pit mines, construction, surface mines and quarries, demolition, civil engineering construction, building construction and so on.

5.DMiningwell D480A has large windows maximize operator visibility.

6.All-in-One display allows operator to monitor machine functions and angle indicator for quick and easy drilling alignment while remaining focused on the drilling.

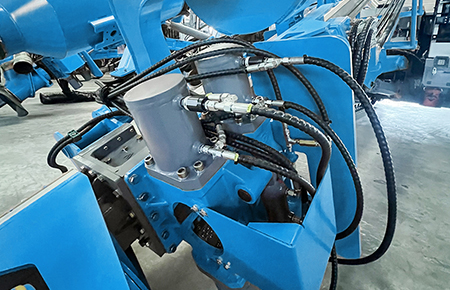

7.Walk-around ground level maintenance provides fast, easy upkeep or repair.

8.D480A Drill Rigs’ angle indicator for quick and easy drilling alignment. Drill hole diameter 5″ – 8″.

9.Reliable dust control system increases suction capacity and provides effective pre-cleaner to reduce the escape of drilling dust. An optional dust suppression system is available for difficult drilling conditions.

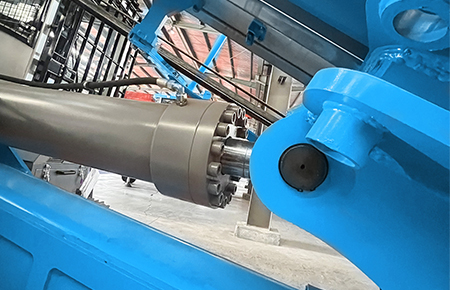

10.Advanced rotary pipe changer allows easy drill pipe changes.

11.High-output compressor increases flushing air, provides faster drilling and decreases bit wear.

.jpg)

.jpg)

.jpg)

.jpg)