Truck-mounted reverse circulation drilling rig MWCF200IV

Brand Name: D miningwell

Certification: CE, ISO

Minimum Order Quantity: 1 set

Packaging Details: 40FR/Bulk Carrier

Delivery Time: 30-45 days

Payment Terms: L/C, T/T, Western Union

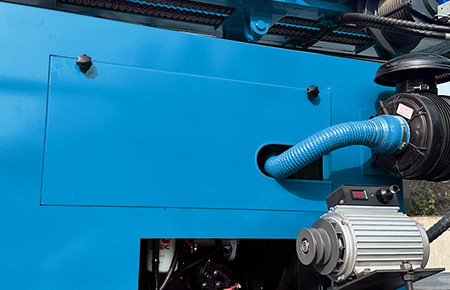

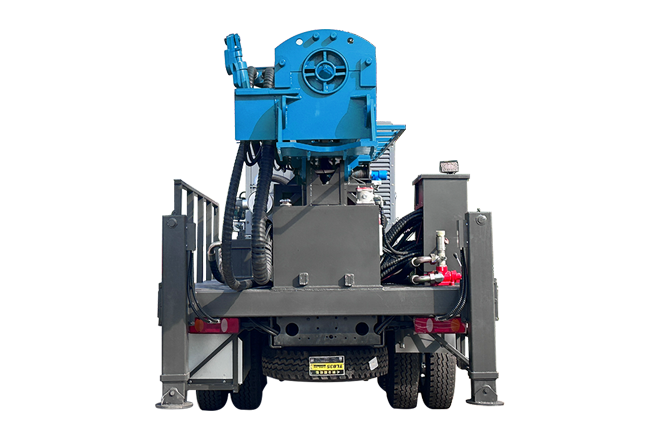

The DMiningwell MWCF200IV truck-mounted reverse circulation power head drilling rig is an independently innovative product of the factory and is a kind of truck-mounted power head rotary drilling rig. The drilling rig selects a 6X4 special drilling truck chassis and is equipped with a Yuchai diesel engine with a national IV emission standard. The diesel generator set, hydraulic system, electronic control system, vacuum pump, drill tower, etc. are all installed on the automobile chassis.

Certification: CE, ISO

Minimum Order Quantity: 1 set

Packaging Details: 40FR/Bulk Carrier

Delivery Time: 30-45 days

Payment Terms: L/C, T/T, Western Union

The DMiningwell MWCF200IV truck-mounted reverse circulation power head drilling rig is an independently innovative product of the factory and is a kind of truck-mounted power head rotary drilling rig. The drilling rig selects a 6X4 special drilling truck chassis and is equipped with a Yuchai diesel engine with a national IV emission standard. The diesel generator set, hydraulic system, electronic control system, vacuum pump, drill tower, etc. are all installed on the automobile chassis.