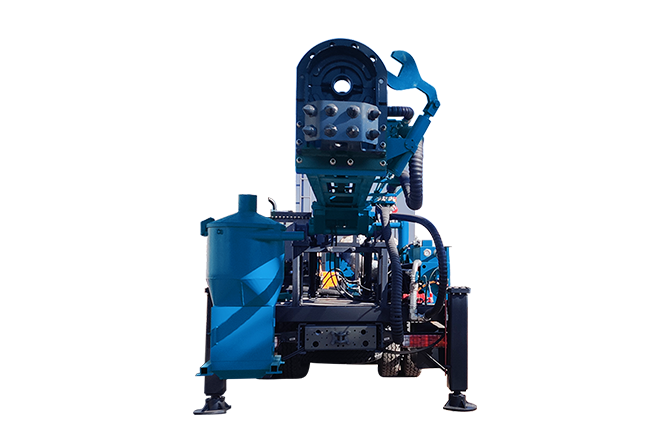

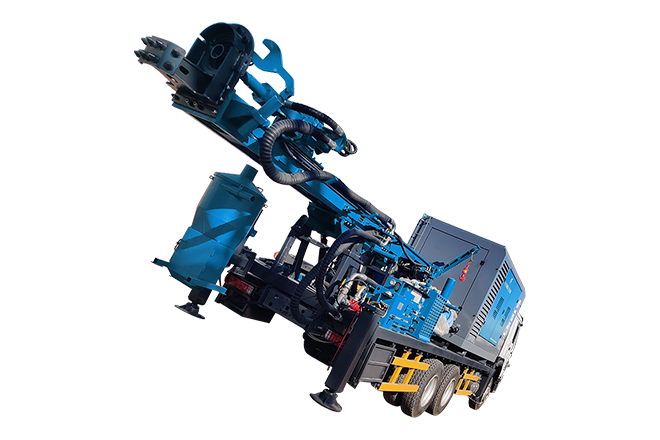

Truck mounted water well drilling rig RD400

Brand Name: D miningwell

Certification: CE, ISO

Minimum Order Quantity: 1 set

Packaging Details: 40FR/Bulk Carrier

Delivery Time: 30-45 days

Payment Terms: L/C, T/T, Western Union

The DMiningwell RD400 water well drilling rig is a remarkable piece of machinery. It is a multifunctional hydraulic drilling equipment designed to excel in the toughest conditions, such as the mountainous areas with harsh environments and complex rock formations for water extraction. The entire vehicle's movements are powered by hydraulic systems, ensuring low labor intensity. With a reasonable vehicle size design, large front and rear outrigger spacing, and high stroke, it can be self-loaded and unloaded without the need for hoisting. The operation is made simple with all control handles integrated into the console, providing a clear interface for real-time monitoring of the rig's operation. The electrical system features integrated wiring with high waterproof rating, and the enclosed outrigger design prevents sediment backflow. Its unique features like the chain wheel with cylindrical roller bearings and skeleton oil seals reduce maintenance costs, and the engine air intake system with 2 - 3 times of filtration strictly protects the engine. The rig also allows for easy maintenance of the engine and hydraulic system through the lifting of the engine compartment by the sliding frame. The smooth and reasonable layout of the hydraulic pipeline extends the service life of the hydraulic hose. The special wear-resistant angle steel structure of the power head's propulsion and lifting track enables adjustable clearance and stable drilling with low resistance. Built with renowned domestic and international core components, the DMiningwell RD400 ensures stable performance and is a top choice for drilling operations.

Certification: CE, ISO

Minimum Order Quantity: 1 set

Packaging Details: 40FR/Bulk Carrier

Delivery Time: 30-45 days

Payment Terms: L/C, T/T, Western Union

The DMiningwell RD400 water well drilling rig is a remarkable piece of machinery. It is a multifunctional hydraulic drilling equipment designed to excel in the toughest conditions, such as the mountainous areas with harsh environments and complex rock formations for water extraction. The entire vehicle's movements are powered by hydraulic systems, ensuring low labor intensity. With a reasonable vehicle size design, large front and rear outrigger spacing, and high stroke, it can be self-loaded and unloaded without the need for hoisting. The operation is made simple with all control handles integrated into the console, providing a clear interface for real-time monitoring of the rig's operation. The electrical system features integrated wiring with high waterproof rating, and the enclosed outrigger design prevents sediment backflow. Its unique features like the chain wheel with cylindrical roller bearings and skeleton oil seals reduce maintenance costs, and the engine air intake system with 2 - 3 times of filtration strictly protects the engine. The rig also allows for easy maintenance of the engine and hydraulic system through the lifting of the engine compartment by the sliding frame. The smooth and reasonable layout of the hydraulic pipeline extends the service life of the hydraulic hose. The special wear-resistant angle steel structure of the power head's propulsion and lifting track enables adjustable clearance and stable drilling with low resistance. Built with renowned domestic and international core components, the DMiningwell RD400 ensures stable performance and is a top choice for drilling operations.

.jpg)

.png)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)